In the complex and challenging drilling operations, Drilling Equipment Valve is undoubtedly a crucial core component. It is like a silent guard, ensuring the safety, efficiency and stability of the entire operation process.

First of all, in terms of controlling the flow of drilling fluid, drilling equipment valves play an irreplaceable role. Drilling fluid plays multiple key roles in the drilling process. It not only cools the drill bit, carries cuttings back to the ground, but also balances the formation pressure. The valve can accurately adjust the flow of drilling fluid to ensure that the drill bit works under appropriate cooling and lubrication conditions. For example, when drilling in different formations, the flow of drilling fluid needs to be adjusted according to the hardness and complexity of the formation. When drilling into hard formations, appropriately increasing the flow can better cool the drill bit and prevent it from overheating and damage; and in some formations that are prone to collapse, reasonable control of the flow can maintain a stable pressure balance and avoid well wall collapse. The drilling equipment valves produced by our company have high-precision flow regulation functions and can meet the flow control needs under various complex working conditions.

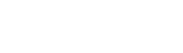

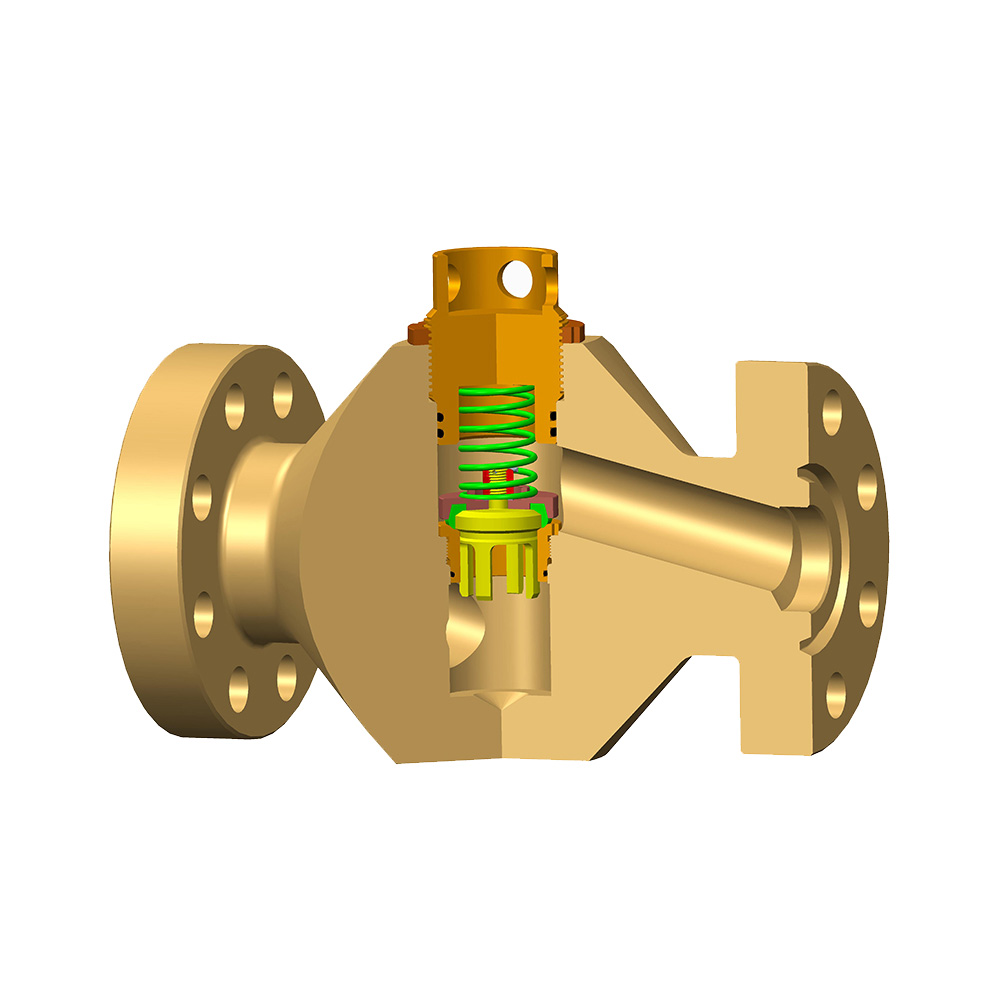

Secondly, the valves of drilling equipment are crucial to maintaining the pressure balance of the drilling system. During the drilling process, the underground formation pressure varies greatly. If the pressure cannot be effectively controlled, it may cause serious accidents such as blowouts. The valve can accurately adjust the pressure at different locations at the wellhead and downhole. It can respond quickly based on the real-time monitored pressure data. For example, when the downhole pressure suddenly increases, the safety valve will automatically open to release excess pressure and ensure the safety of the entire drilling system. Our valves use advanced pressure sensing technology and fast response mechanism, which can complete the pressure adjustment action in an instant and provide reliable pressure protection for drilling operations.

Furthermore, the valves of drilling equipment play a key role in preventing the backflow of drilling fluid. When the drilling operation is suspended or a certain stage is completed, it is necessary to prevent the backflow of drilling fluid to avoid damage to the equipment or affect subsequent operations. The check function of the valve can effectively prevent the reverse flow of drilling fluid and ensure the stability of the entire drilling system. The valves of our company focus on the optimization of check performance in design, and adopt special sealing structures and materials to ensure that the backflow phenomenon can still be reliably prevented during long-term use.

In addition, the durability and reliability of drilling equipment valves directly affect the continuity of drilling operations. The drilling site environment is harsh, and factors such as high temperature, high pressure, and highly corrosive substances are a huge test for valves. Our company's valves are made of high-strength, corrosion-resistant materials and undergo strict quality inspections. They can operate stably for a long time in harsh environments, reduce operation interruptions caused by valve failures, improve drilling efficiency, and reduce costs.

+86-18066199628

Product Search

Exit Menu

news

News categories

Product categories

RECENT POSTS

-

What are the specific application scenarios of valves in oil fields?

2024-06-01 -

Can the mud gate valve be closed quickly in the event of a blowout?

2024-06-02 -

What are the uses of valves for oil fields?

2024-06-10 -

Welcome to Zhonglin Oil Equipment!

2024-07-08 -

In which industries is GATE VALVE widely used?

2024-09-14

What key role does Drilling Equipment Valve play in drilling operations?

-

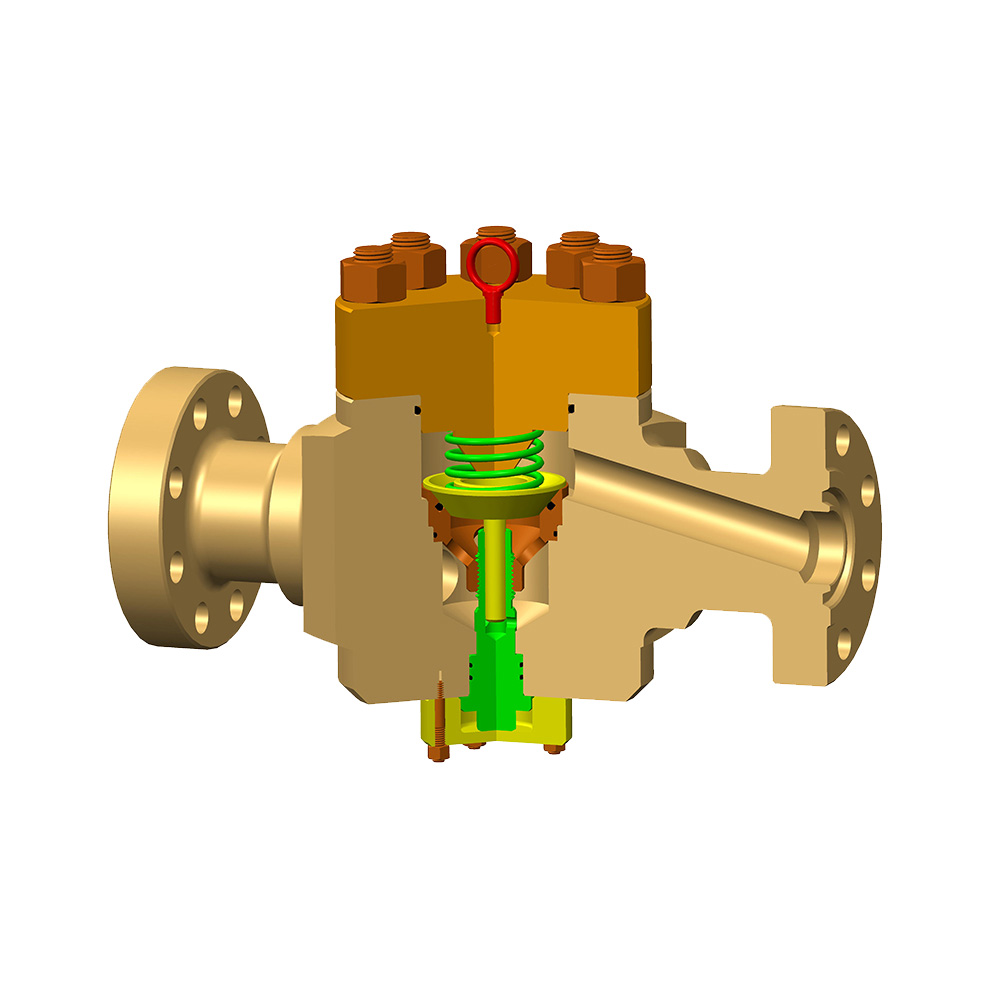

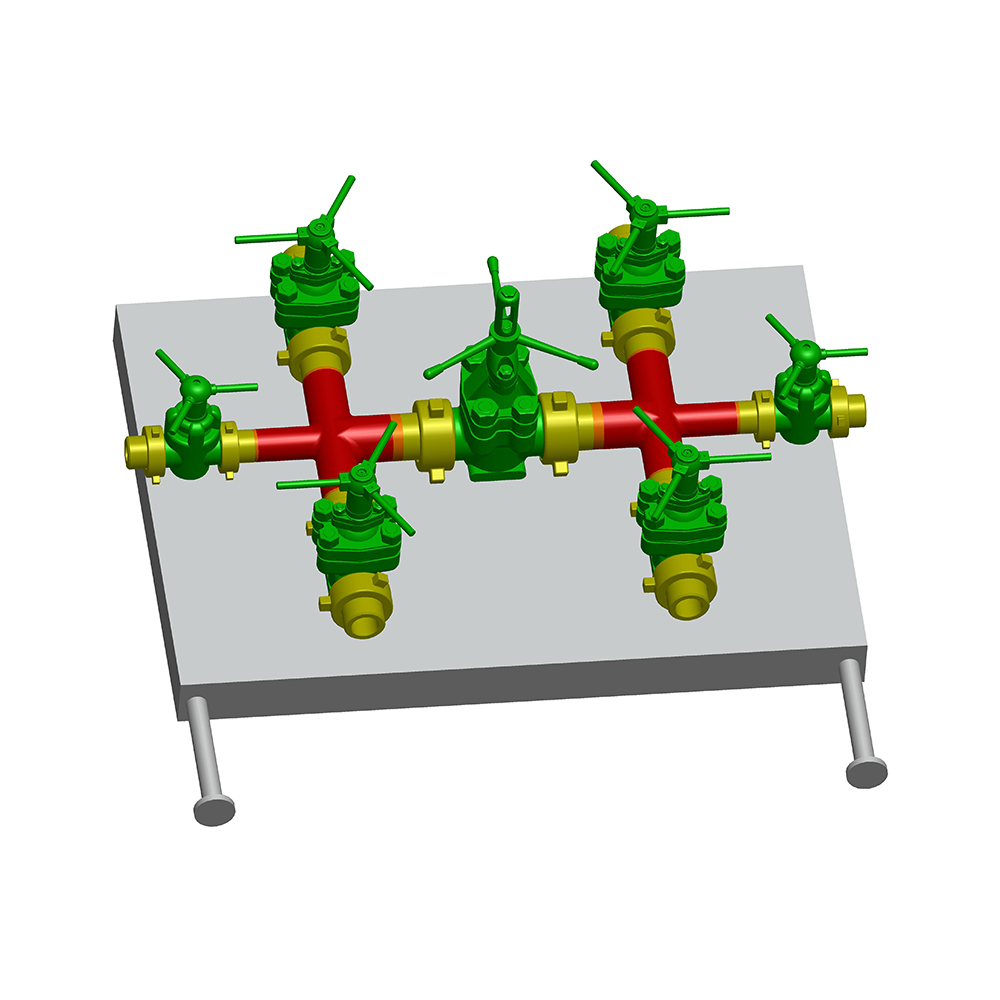

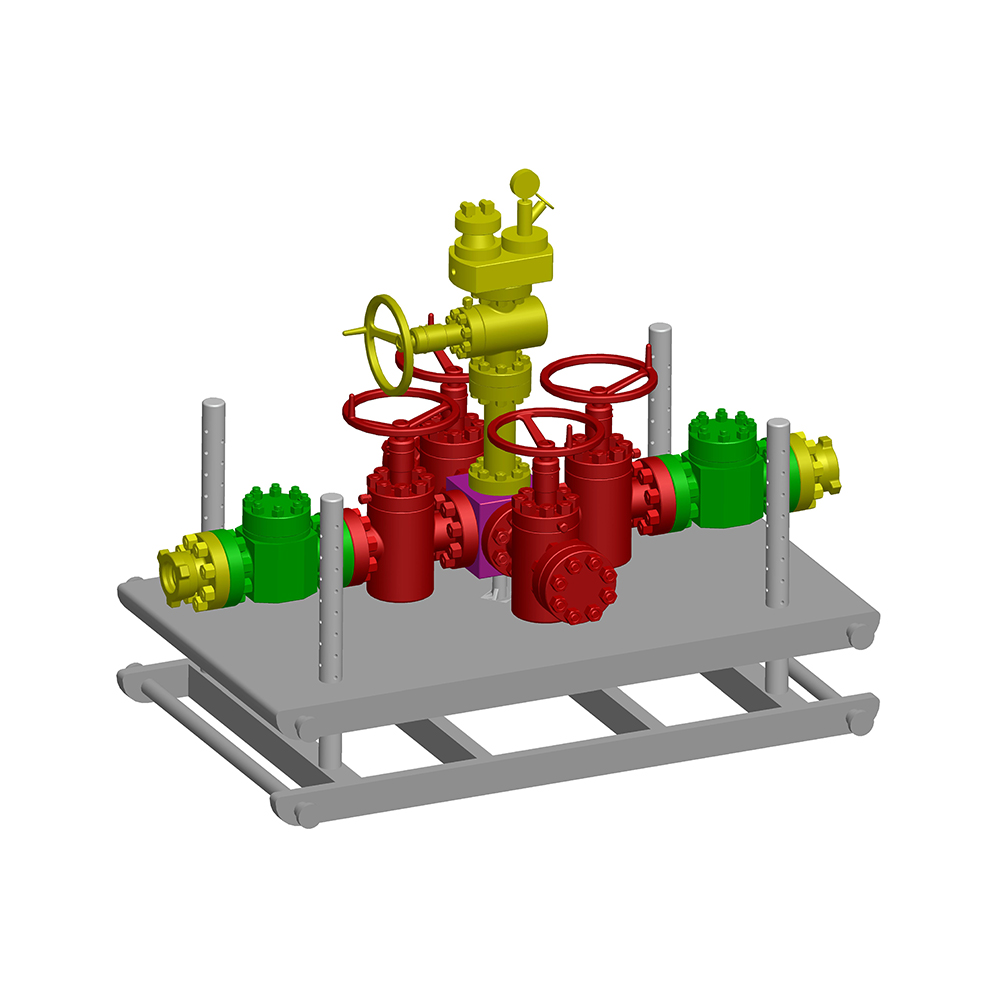

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

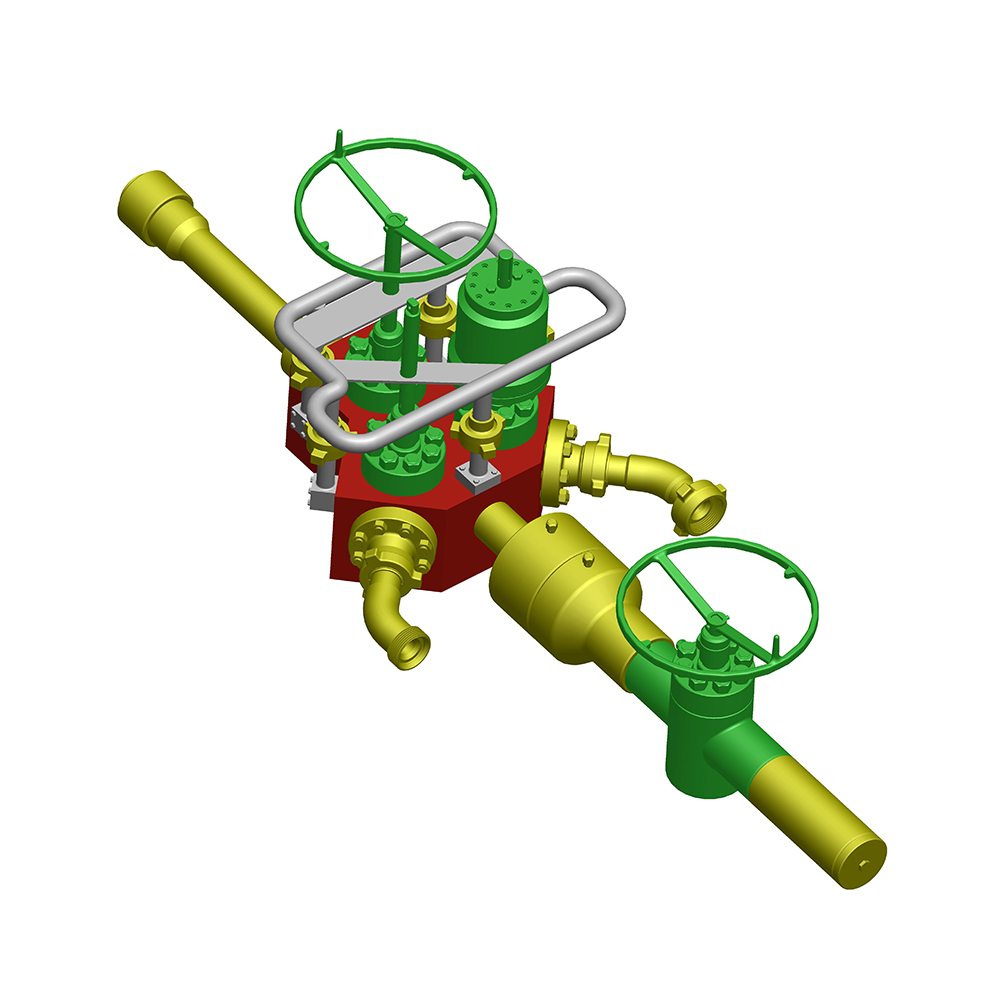

Flowhead sizes:1-13/16" ~9”Pressure Rating:5000psi- 15000psiMax.Tensile Rating:435,000 to 1,500,000 Ibs at 0PSIUpper and lower units are coupled with a load-bearing quick union for easy assembly and d...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details

Contact Zhonglin Support Team for any Inquiry

Mob:

+86-18066199628/ +86-18805110688

Email:

[email protected] / [email protected]

Add: 88 Ronghua Road Yancheng New Hi-Tech Industrial Development Zone Yancheng, Jinagsu People's Republic of China