Drilling equipment valves play a crucial role in the drilling process, and they possess several main functions that are essential for the smooth operation of drilling operations.

One of the primary functions of a drilling equipment valve is to control the flow of drilling fluid. Drilling fluid, also known as mud, is circulated throughout the drilling system to cool and lubricate the drill bit, carry cuttings to the surface, and maintain pressure in the wellbore. The valve can precisely regulate the rate at which the drilling fluid enters and exits the system. For example, during normal drilling operations, the valve can be adjusted to ensure a steady flow of fluid to the drill bit, providing optimal cooling and lubrication. In the event of a problem, such as a sudden increase in pressure or the need to change the drilling parameters, the valve can be quickly manipulated to modify the fluid flow accordingly.

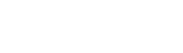

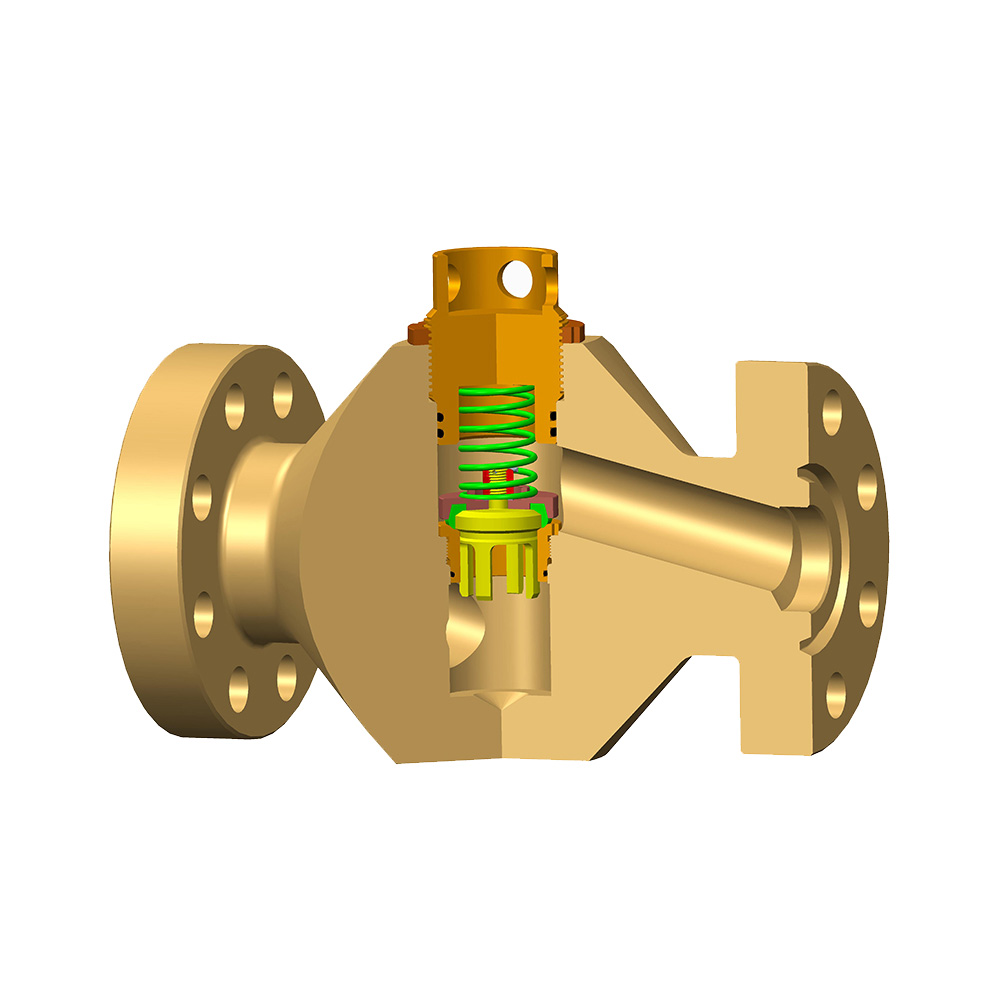

Another important function is pressure control. The valve helps to maintain the desired pressure within the drilling system. In deep - well drilling, high pressures can build up due to the weight of the drilling fluid column and the geological conditions. The valve acts as a safeguard against over - pressure situations. It can be adjusted to relieve excess pressure, preventing potential blowouts that could cause serious damage to the drilling equipment and endanger the safety of the crew. At the same time, it can also maintain sufficient pressure to support the wellbore walls and prevent collapses.

Drilling equipment valves also contribute to the isolation of different sections of the drilling system. This is particularly useful during maintenance or when changing components. By closing specific valves, certain parts of the system can be isolated from the rest, allowing for repairs or replacements without disrupting the entire operation. For instance, if a section of the drill string needs to be inspected or replaced, the relevant valves can be closed to stop the flow of fluid to that area and create a safe working environment.

In addition, these valves enable the diversion of fluid flow. In some complex drilling scenarios, such as when dealing with multiple wells or when there is a need to redirect the flow of drilling fluid for specific purposes, the valves can be configured to change the direction of the fluid. This flexibility in fluid flow management is vital for optimizing the drilling process and adapting to various drilling requirements.

+86-18066199628

Product Search

Exit Menu

news

News categories

Product categories

RECENT POSTS

-

What are the specific application scenarios of valves in oil fields?

2024-06-01 -

Can the mud gate valve be closed quickly in the event of a blowout?

2024-06-02 -

What are the uses of valves for oil fields?

2024-06-10 -

Welcome to Zhonglin Oil Equipment!

2024-07-08 -

In which industries is GATE VALVE widely used?

2024-09-14

What Are the Main Functions of a Drilling Equipment Valve?

-

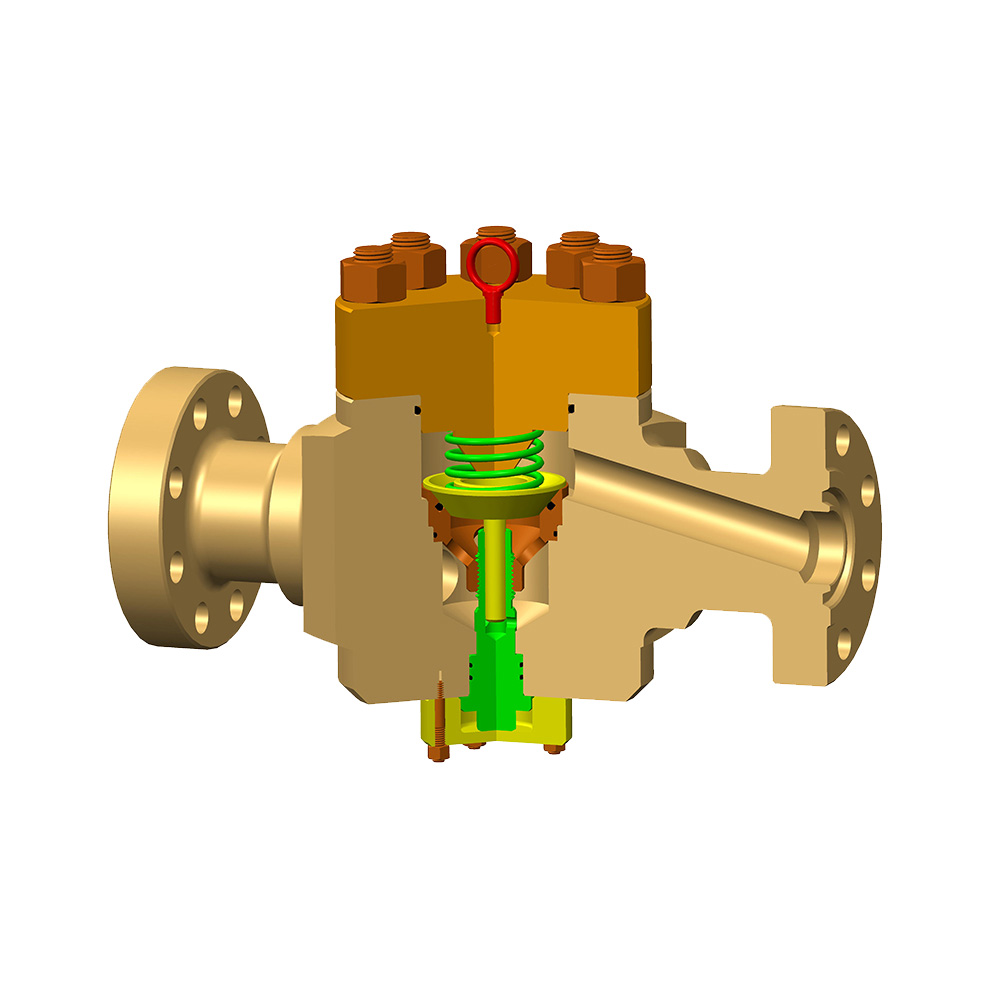

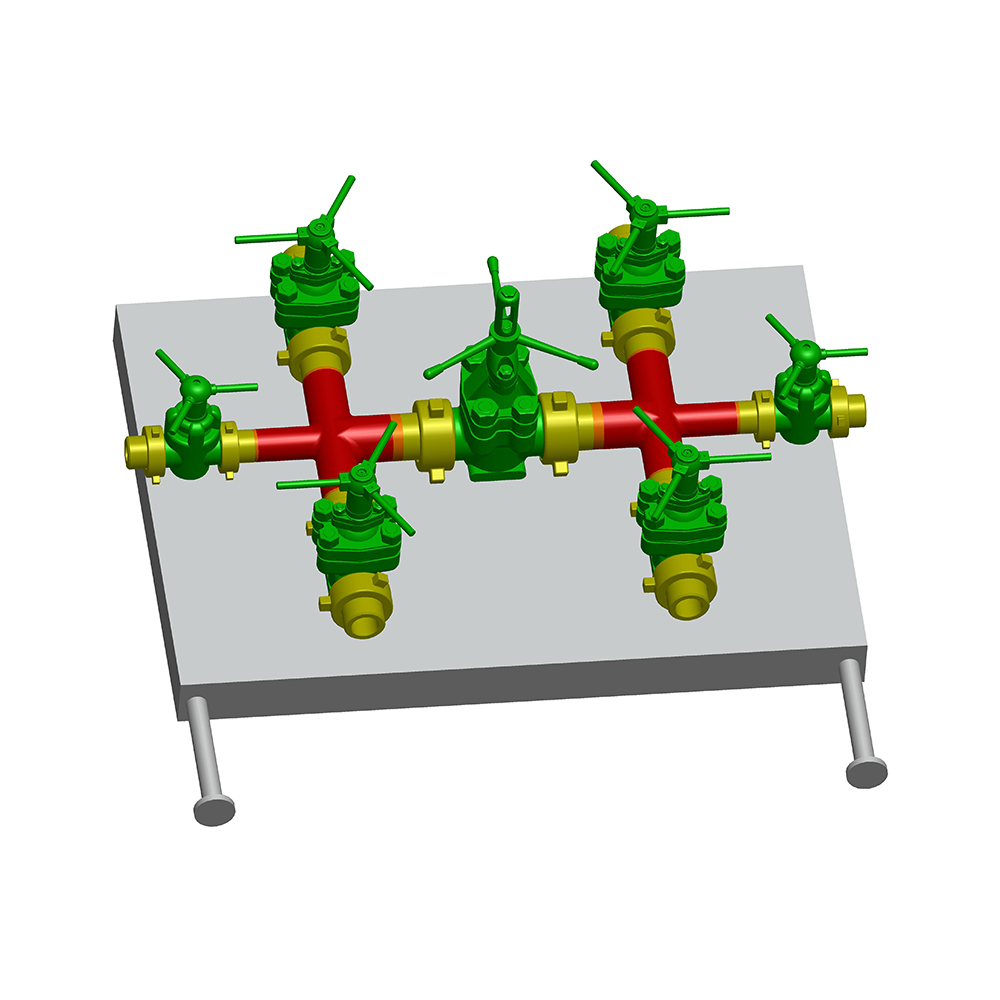

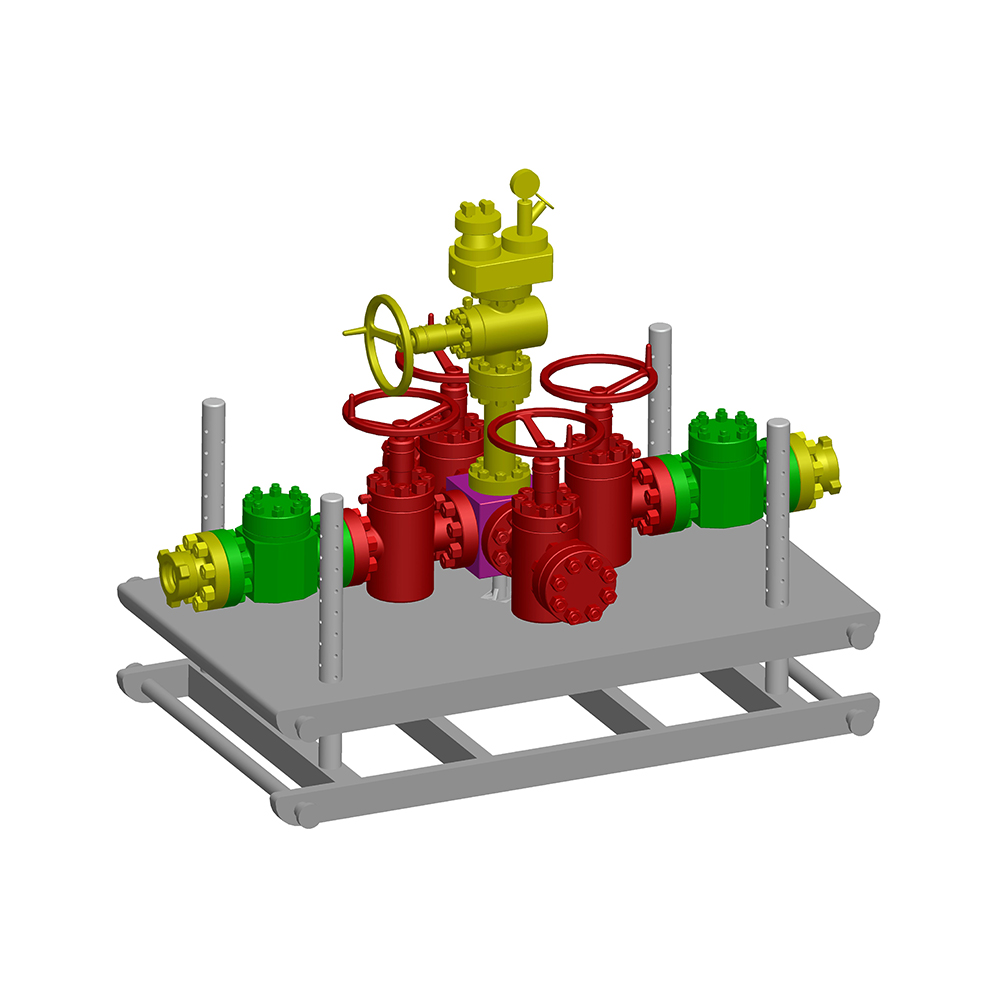

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

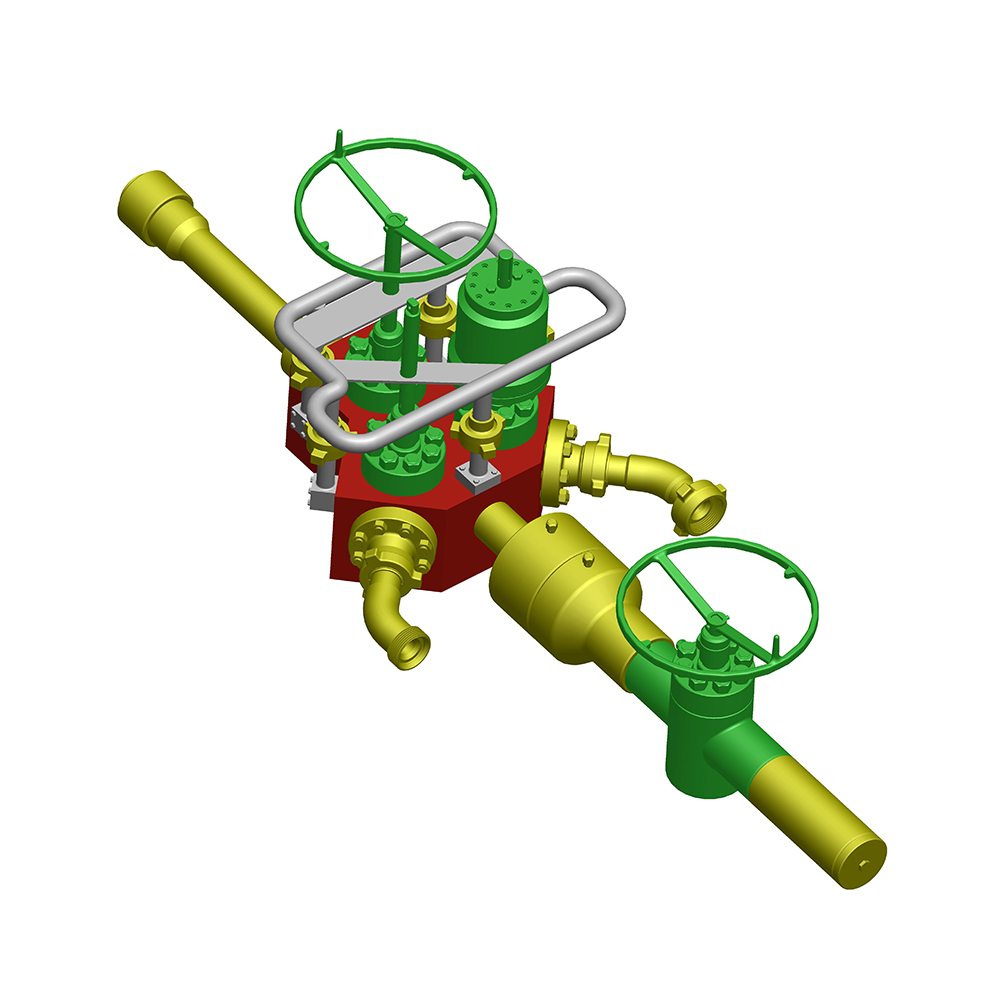

Flowhead sizes:1-13/16" ~9”Pressure Rating:5000psi- 15000psiMax.Tensile Rating:435,000 to 1,500,000 Ibs at 0PSIUpper and lower units are coupled with a load-bearing quick union for easy assembly and d...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details

Contact Zhonglin Support Team for any Inquiry

Mob:

+86-18066199628/ +86-18805110688

Email:

[email protected] / [email protected]

Add: 88 Ronghua Road Yancheng New Hi-Tech Industrial Development Zone Yancheng, Jinagsu People's Republic of China