In medical equipment, the aseptic sealing of Tubing Head Adapter is crucial. Medical fluid transfer systems need to ensure aseptic operation to prevent cross infection. Therefore, the material of Tubing Head Adapter needs to be selected from medical grade stainless steel or polymer materials, which have good biocompatibility and corrosion resistance and can undergo strict sterilization. In addition, the seamless connection and multiple sealing structures in design are also the key to ensure sterility.

In the chemical industry, Tubing Head Adapter needs to withstand the erosion of highly corrosive chemicals. To this end, it is necessary to use high-strength and corrosion-resistant alloy materials. At the same time, the structural design needs to be optimized to enhance the pressure resistance and prevent leakage. In addition, the sealing performance and material corrosion resistance of Tubing Head Adapter also need to be strictly tested to ensure long-term stable operation.

The food and beverage industry has extremely high requirements for hygiene standards. The design of Tubing Head Adapter must comply with the principle of easy cleaning and maintenance to prevent bacterial growth. In terms of materials, food-grade stainless steel or other materials that meet hygiene standards are preferred. In addition, the sealing structure needs to be simple and easy to disassemble for thorough cleaning and disinfection.

In the semiconductor manufacturing process, the transportation of high-purity gases and liquids places extremely high demands on the material and sealing of THA. Tubing Head Adapter needs to use precipitate-free, corrosion-resistant materials, and ensure its purity through precision machining and vacuum degassing. In the sealing design, extremely high precision is required to prevent gas or liquid leakage, which affects the quality of semiconductor products.

In the oil and gas mining and transportation system, Tubing Head Adapter faces a severe environment of high pressure and high temperature. In order to ensure its pressure and high temperature resistance, Tubing Head Adapter needs to use high-strength alloy materials, and improve its strength and toughness through precision machining and heat treatment. In addition, multiple sealing structures and optimized designs are also the key to preventing leakage and ensuring safe and stable operation of the system.

+86-18066199628

Product Search

Exit Menu

news

News categories

Product categories

RECENT POSTS

-

What are the specific application scenarios of valves in oil fields?

2024-06-01 -

Can the mud gate valve be closed quickly in the event of a blowout?

2024-06-02 -

What are the uses of valves for oil fields?

2024-06-10 -

Welcome to Zhonglin Oil Equipment!

2024-07-08 -

In which industries is GATE VALVE widely used?

2024-09-14

How to ensure the good performance and reliability of Tubing Head Adapter in multi-industry applications?

-

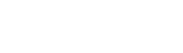

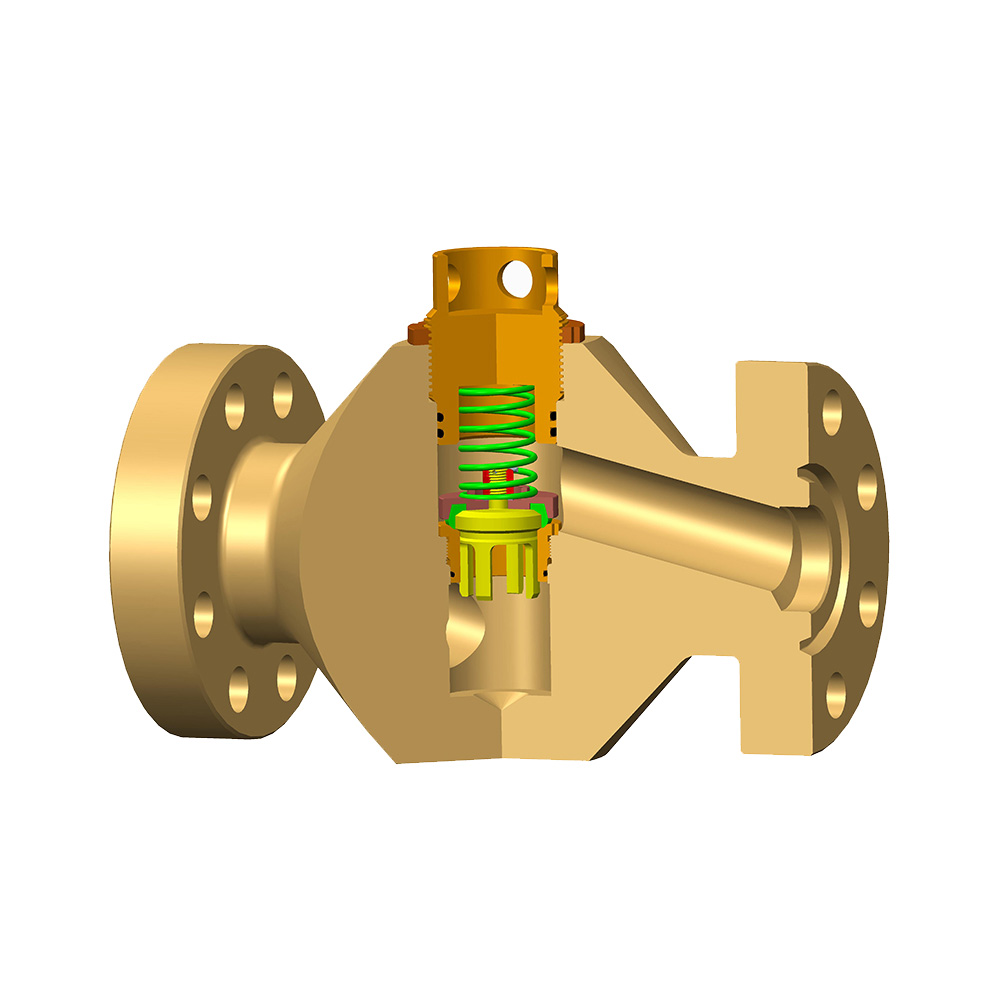

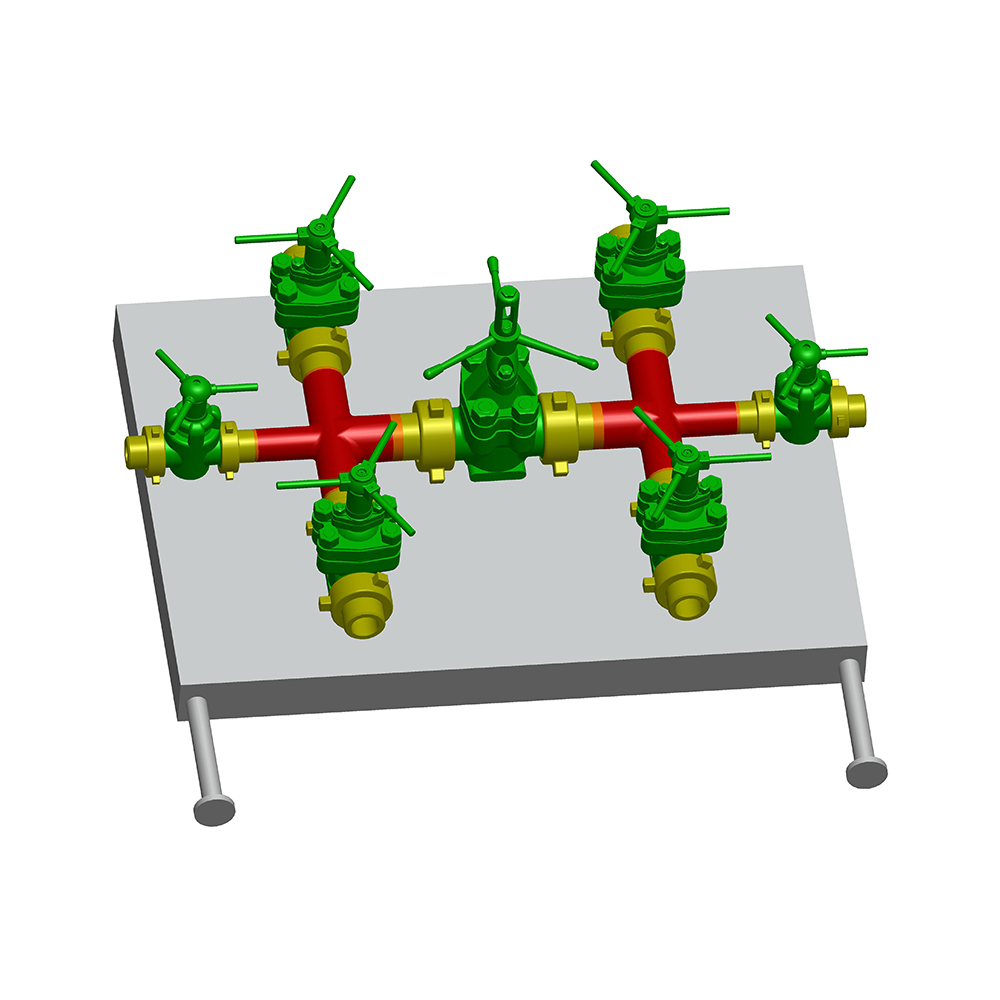

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

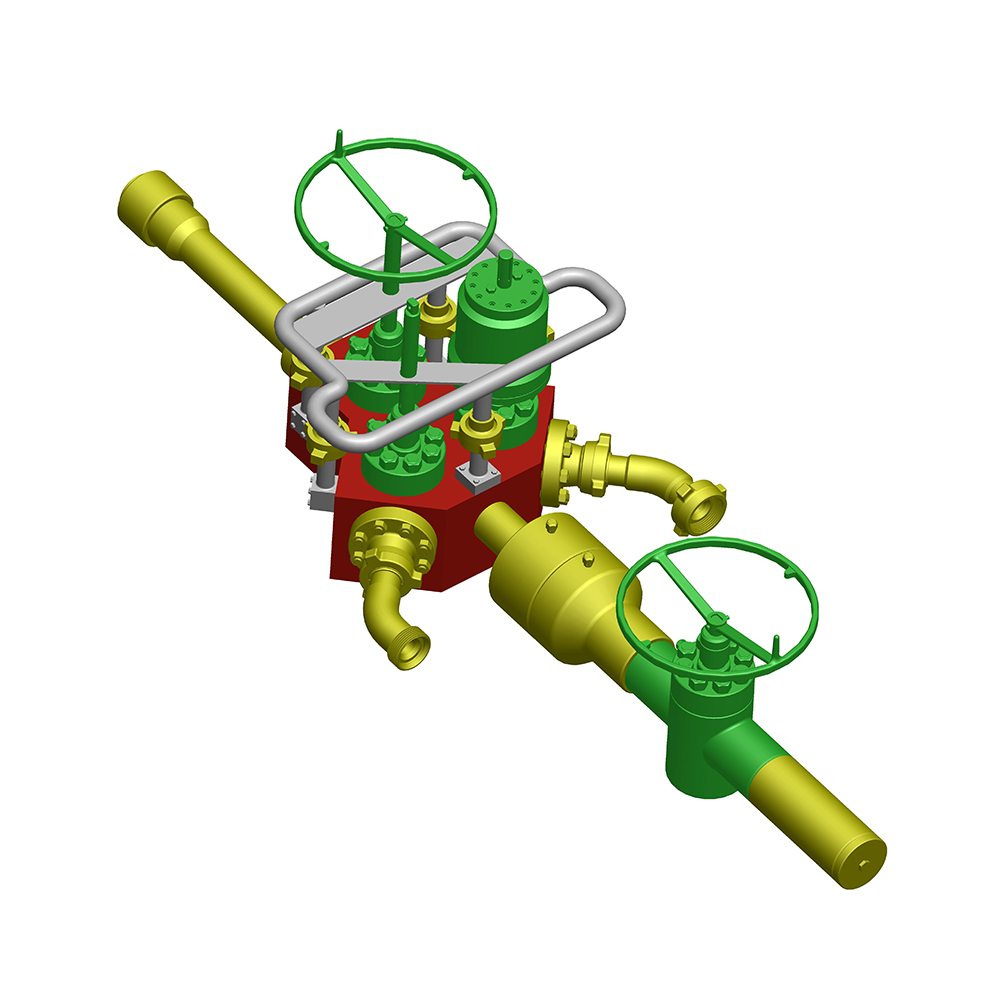

Flowhead sizes:1-13/16" ~9”Pressure Rating:5000psi- 15000psiMax.Tensile Rating:435,000 to 1,500,000 Ibs at 0PSIUpper and lower units are coupled with a load-bearing quick union for easy assembly and d...

See Details -

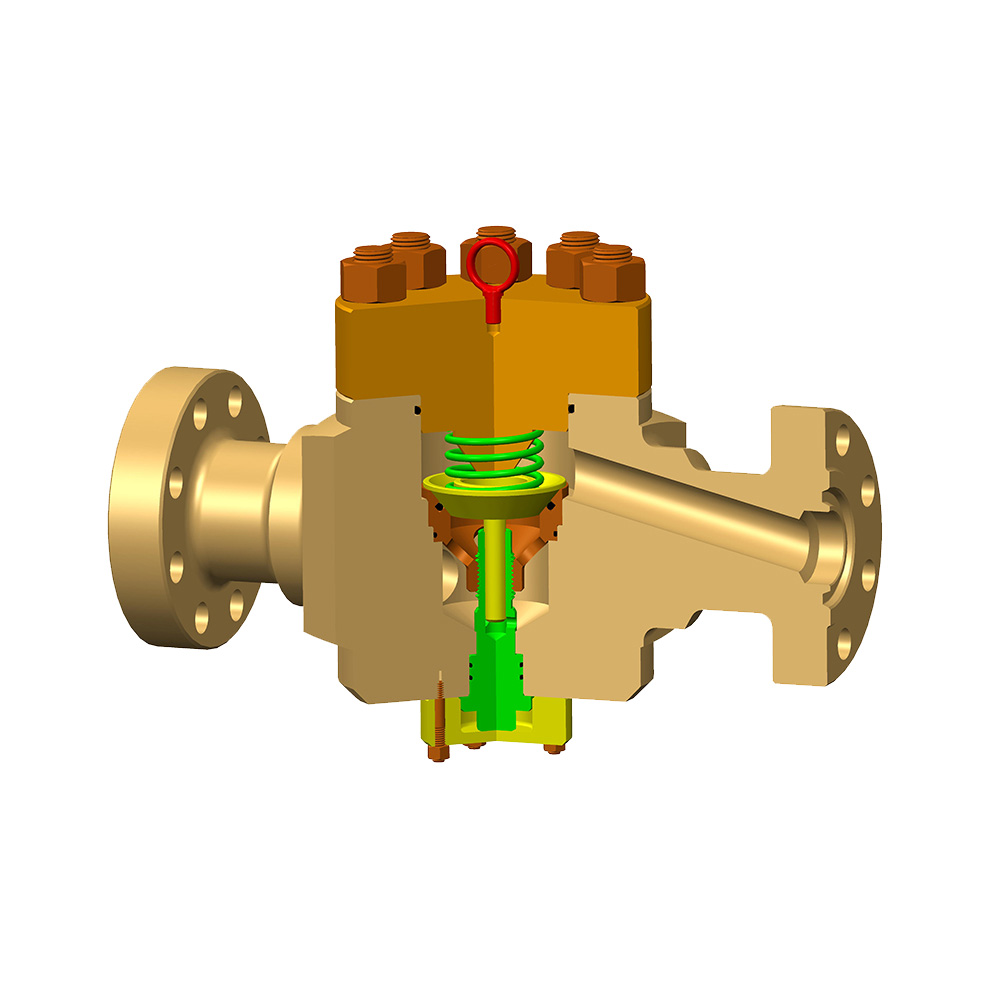

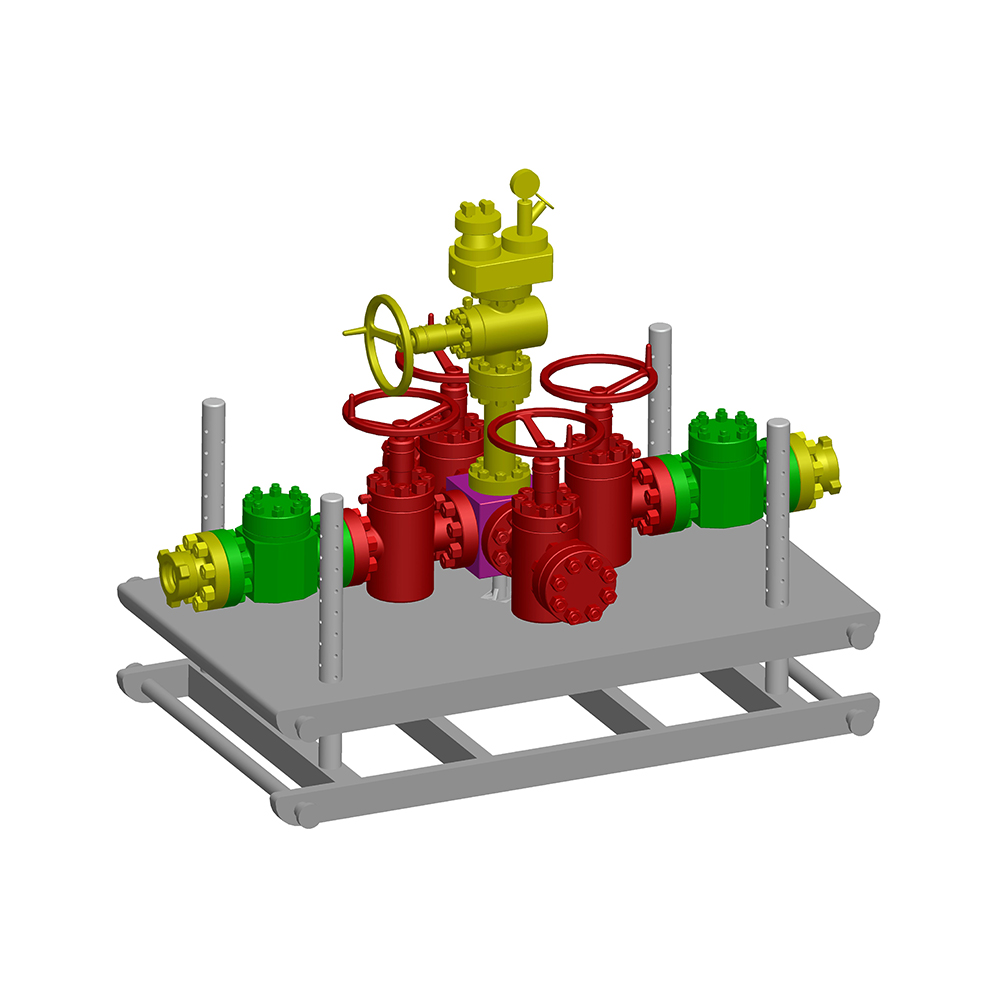

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details

Contact Zhonglin Support Team for any Inquiry

Mob:

+86-18066199628/ +86-18805110688

Email:

[email protected] / [email protected]

Add: 88 Ronghua Road Yancheng New Hi-Tech Industrial Development Zone Yancheng, Jinagsu People's Republic of China