Casing Hanger is located between casings and is an important bridge connecting surface casing and technical casing or production casing. It not only ensures a stable connection between casings, but also provides necessary support for casings through its structural design, effectively resisting the huge pressure from the formation and inside the wellbore. This connection and support function provides a solid guarantee for the structural integrity of oil and gas wells.

In the process of oil and gas production, it is crucial to prevent leakage of formation fluids. Casing Hanger is designed with a precise sealing structure, such as multi-layer soft stacking seals or metal hard seals, which can fit tightly to the casing wall and effectively prevent formation fluids from flowing upward through the gaps between casings. This sealing performance not only ensures the safety of the wellbore, but also prevents environmental pollution and economic losses.

From the drilling stage to the production stage, Casing Hanger always guards the safety and stability of oil and gas wells. During the drilling process, it can protect the drilled casing from the influence of drilling fluid and other drilling operations; in the production stage, it continues to play its supporting and sealing role to ensure that oil and gas can be smoothly extracted from the formation and transported to the ground.

As oil and gas extraction advances to deeper, hotter and more pressurized formations, Casing Hangers face more severe challenges in high temperature and high pressure environments. Therefore, the choice of materials becomes the key. Modern Casing Hangers are usually made of high temperature resistant alloy materials, such as nickel-based alloys, chromium-molybdenum steel, etc. These materials can still maintain excellent mechanical properties and chemical stability under high temperature and high pressure. At the same time, the sealing material must also have good high temperature and pressure resistance to ensure long-term stable sealing effect.

In order to further improve the sealing performance of Casing Hangers, the industry continues to explore new sealing technologies and materials. For example, multi-layer soft stacking seals improve the elasticity and wear resistance of the sealing surface by optimizing the material formula and structural design; while metal hard seals achieve higher sealing accuracy and reliability through precision processing and heat treatment processes. In addition, the application of intelligent monitoring systems also makes real-time monitoring and early warning of sealing performance possible.

With the continuous development of automation and intelligent technology, the installation, maintenance and monitoring of Casing Hanger have also ushered in new changes. The automated installation system can reduce manual intervention and improve installation accuracy and efficiency; while the intelligent monitoring system can monitor the working status of the Casing Hanger in real time, detect and warn potential problems in a timely manner, and provide strong protection for the safe production of oil and gas wells.

+86-18066199628

Product Search

Exit Menu

news

News categories

Product categories

RECENT POSTS

-

What are the specific application scenarios of valves in oil fields?

2024-06-01 -

Can the mud gate valve be closed quickly in the event of a blowout?

2024-06-02 -

What are the uses of valves for oil fields?

2024-06-10 -

Welcome to Zhonglin Oil Equipment!

2024-07-08 -

In which industries is GATE VALVE widely used?

2024-09-14

How does Casing Hanger respond to different environmental challenges with innovative technology?

-

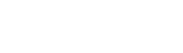

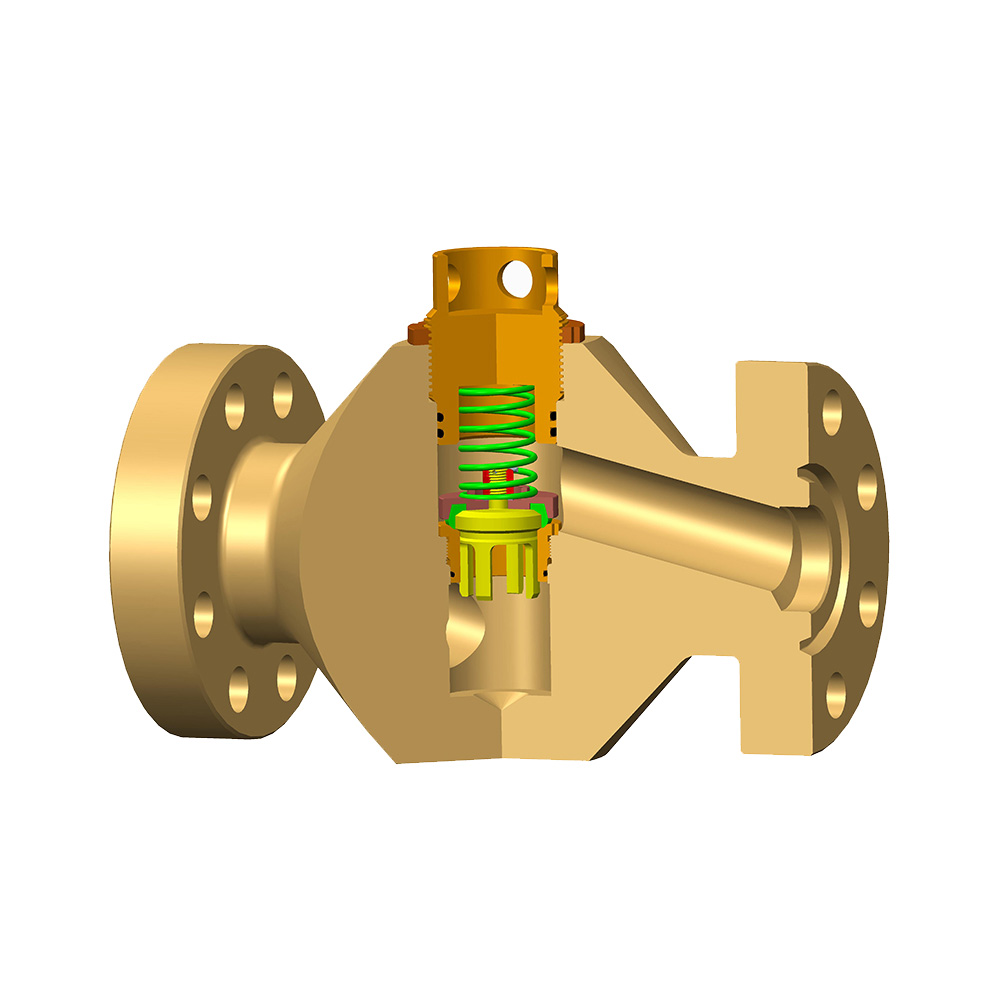

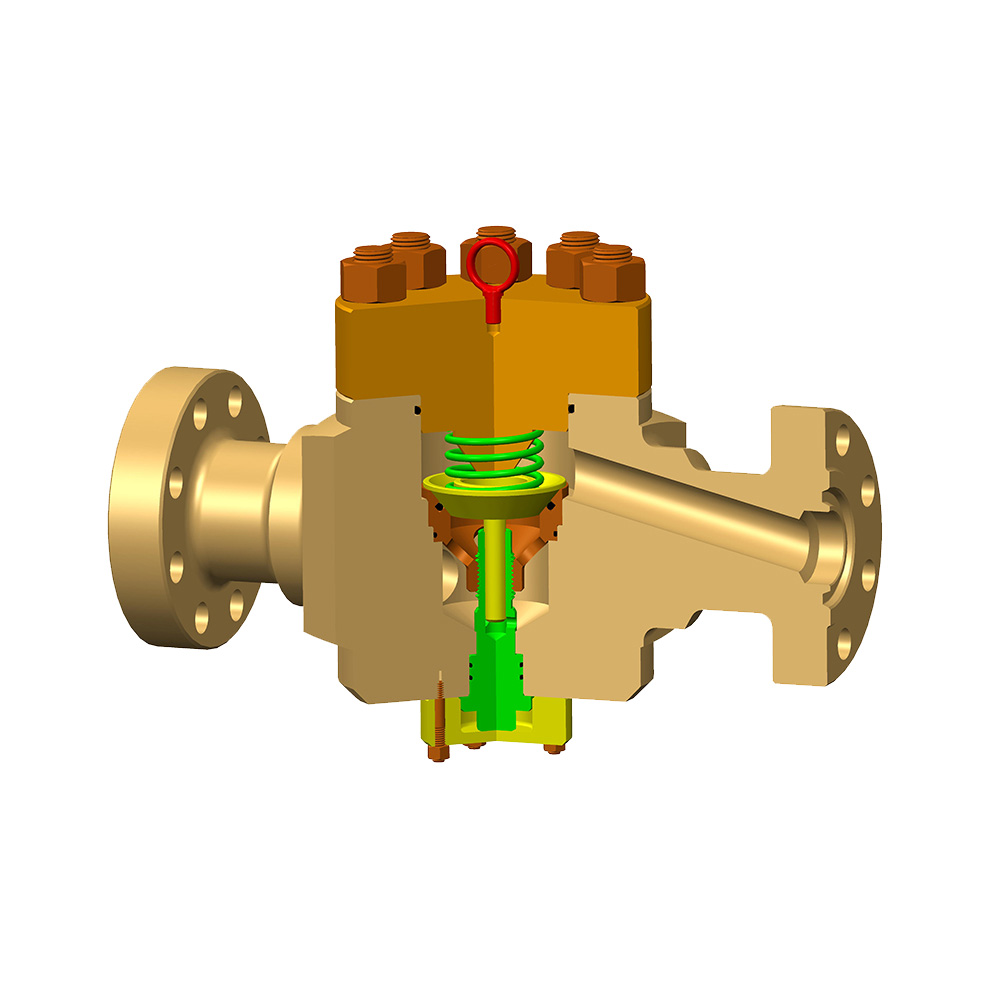

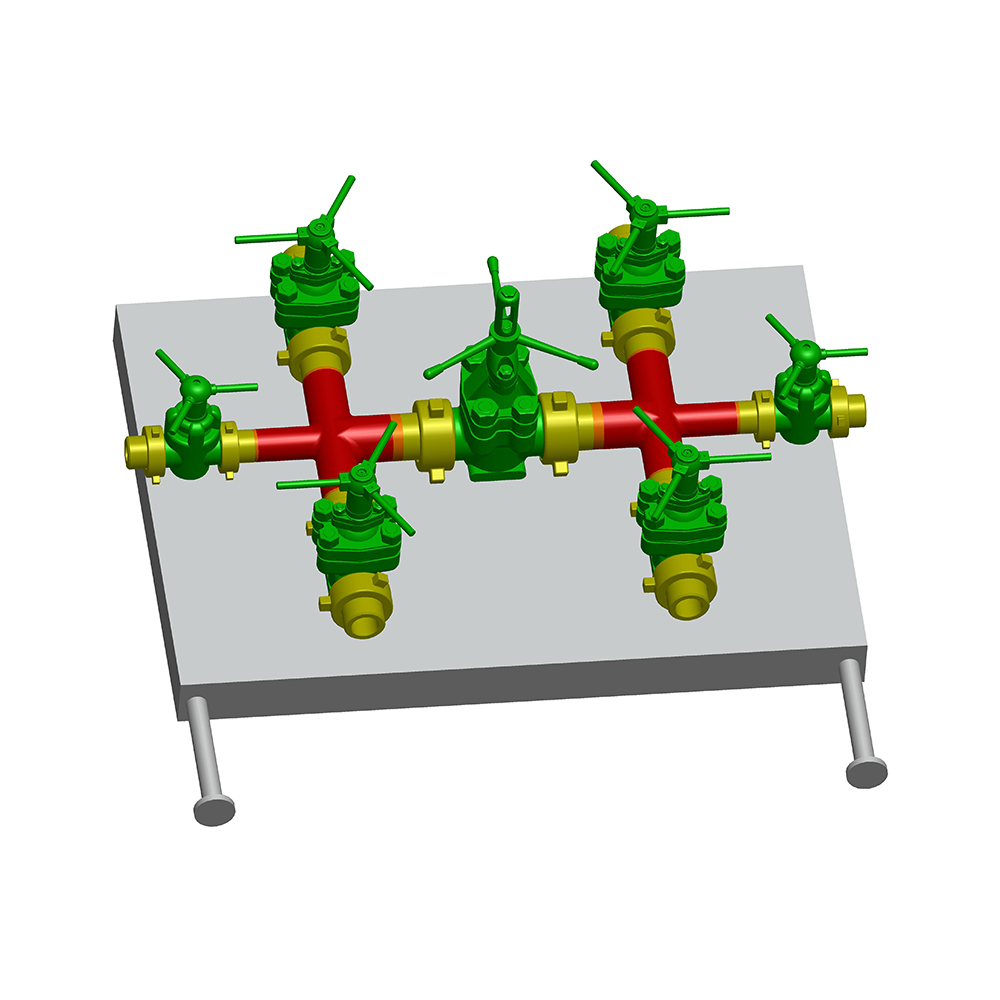

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

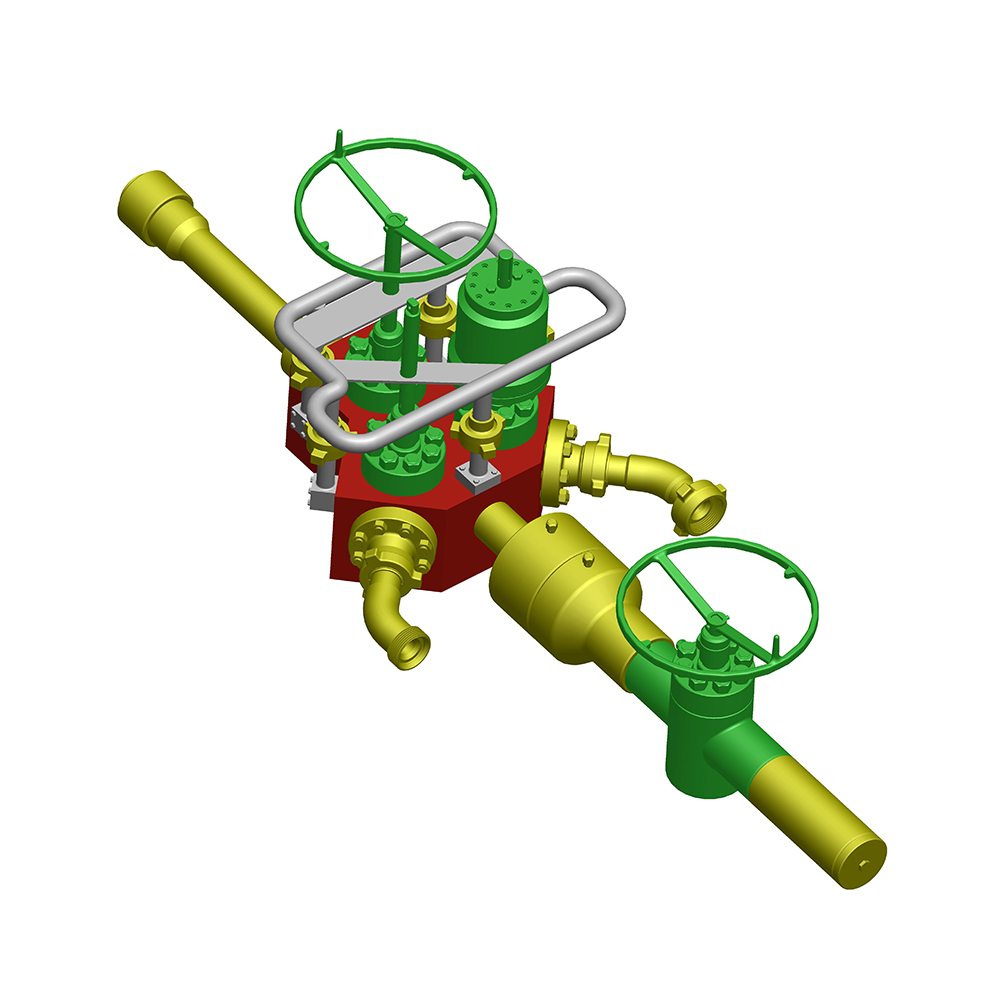

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

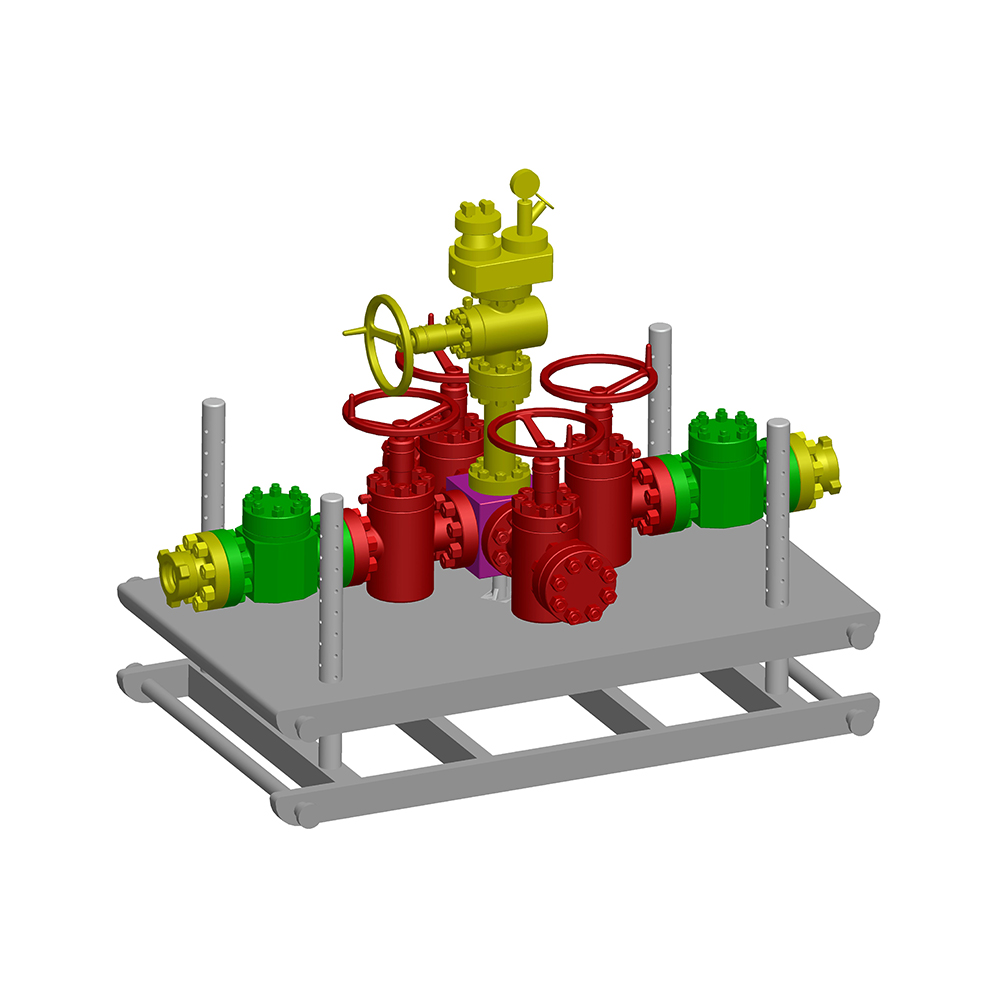

Flowhead sizes:1-13/16" ~9”Pressure Rating:5000psi- 15000psiMax.Tensile Rating:435,000 to 1,500,000 Ibs at 0PSIUpper and lower units are coupled with a load-bearing quick union for easy assembly and d...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details

Contact Zhonglin Support Team for any Inquiry

Mob:

+86-18066199628/ +86-18805110688

Email:

[email protected] / [email protected]

Add: 88 Ronghua Road Yancheng New Hi-Tech Industrial Development Zone Yancheng, Jinagsu People's Republic of China