In complex drilling operations, choosing the right Drilling Equipment Valve is the key to ensuring operational safety and efficiency. As the core component of drilling fluid, gas and pressure control, the performance of the valve directly affects the smooth progress of drilling operations.

Understand the drilling environment: Different geological structures, drilling depths, well fluid types and pressure conditions have completely different requirements for valves. Before selecting a valve, a comprehensive assessment of the drilling environment is required, including but not limited to geological hardness, fluid corrosiveness, temperature range and pressure level.

Matching valve types and functions: According to drilling requirements, there are various types of valves, such as gate valves, stop valves, ball valves and check valves. Gate valves are suitable for large-diameter pipelines that need to be fully opened and closed; stop valves are more suitable for occasions where flow needs to be adjusted; ball valves are known for their fast opening and closing and good sealing; check valves are used to prevent medium backflow. Clarifying the functional requirements of the valve is the key to selection.

Material and corrosion resistance: In the drilling environment, valves often face the challenges of corrosion, wear and high temperature and high pressure. Selecting materials with high corrosion resistance, high strength and high temperature resistance, such as stainless steel, alloy steel or special coating materials, is an important means to extend the life of the valve and ensure the safety of the operation.

Pressure and flow control: In drilling operations, accurate control of pressure and flow is essential. Selecting valves with precise adjustment functions, combined with pressure sensors and flow controllers, can realize the automation and intelligence of the drilling process and improve operational efficiency and safety.

To select a suitable Drilling Equipment Valve, it is necessary to comprehensively consider the drilling environment, valve type and function, material, pressure and flow control, brand and after-sales service and other factors. Only accurate matching can ensure the smooth progress of drilling operations and improve overall operational efficiency and safety.

Product Search

Exit Menu

news

News categories

Product categories

RECENT POSTS

-

What are the specific application scenarios of valves in oil fields?

2024-06-01 -

Can the mud gate valve be closed quickly in the event of a blowout?

2024-06-02 -

What are the uses of valves for oil fields?

2024-06-10 -

Welcome to Zhonglin Oil Equipment!

2024-07-08 -

In which industries is GATE VALVE widely used?

2024-09-14

How to choose the right Drilling Equipment Valve to adapt to different drilling environments?

-

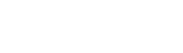

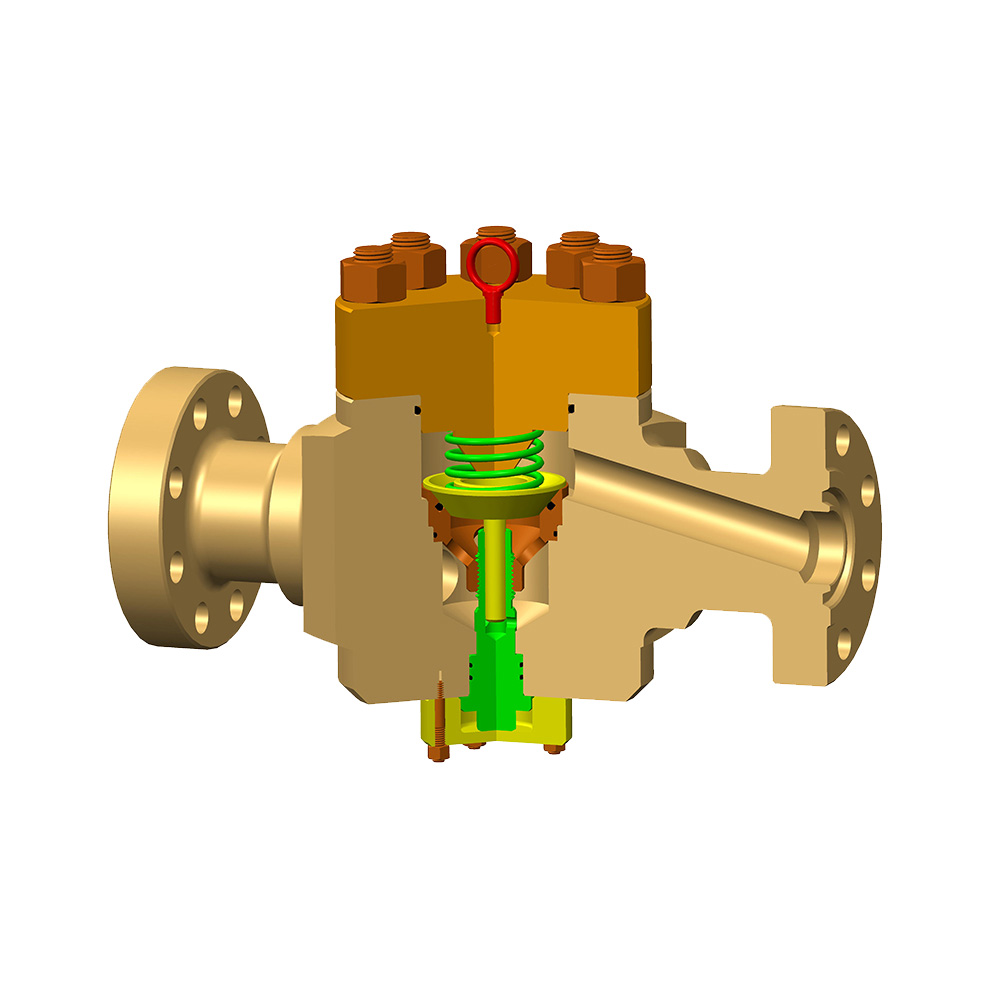

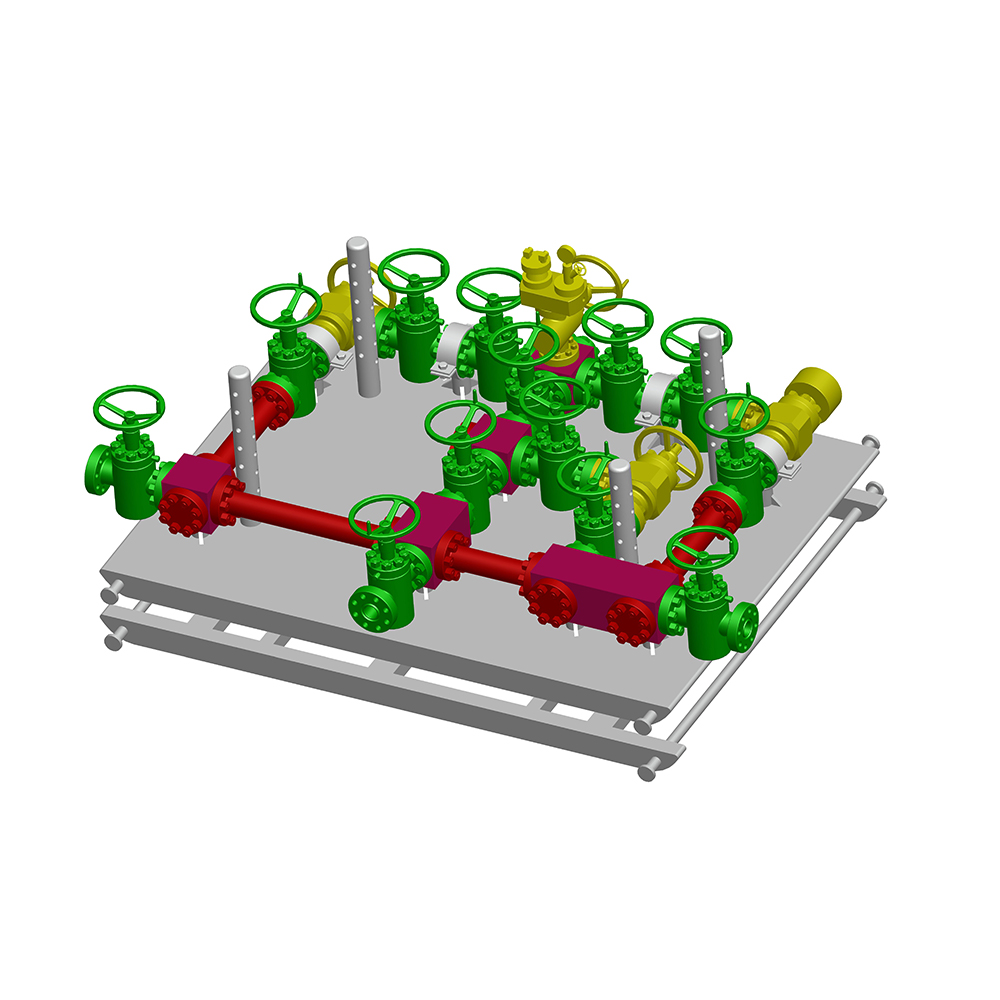

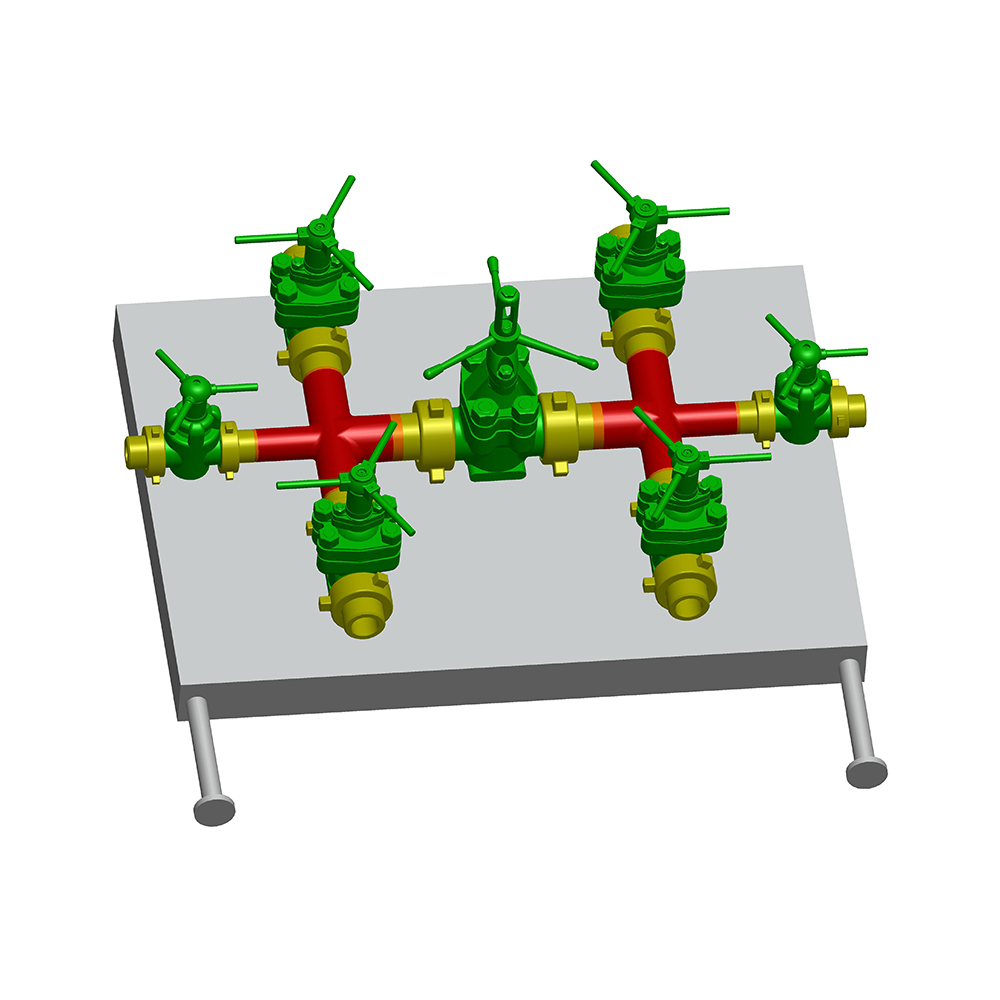

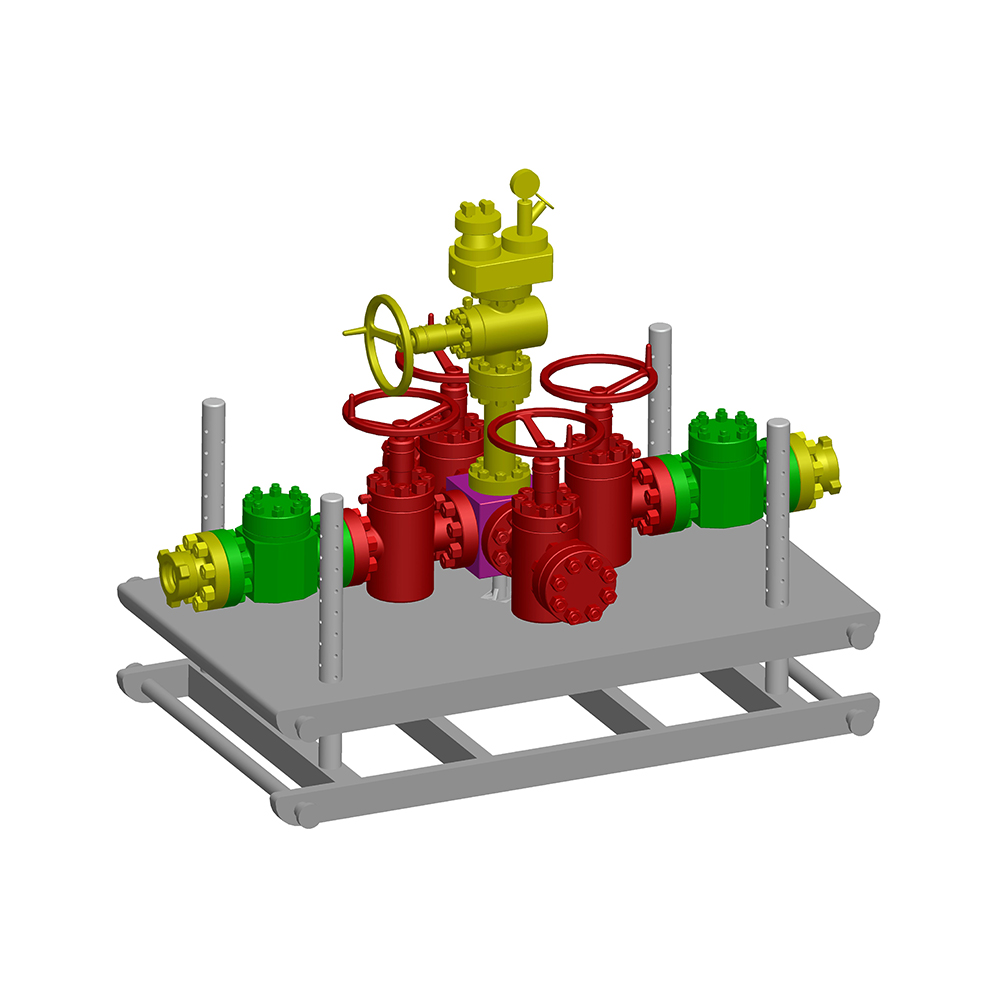

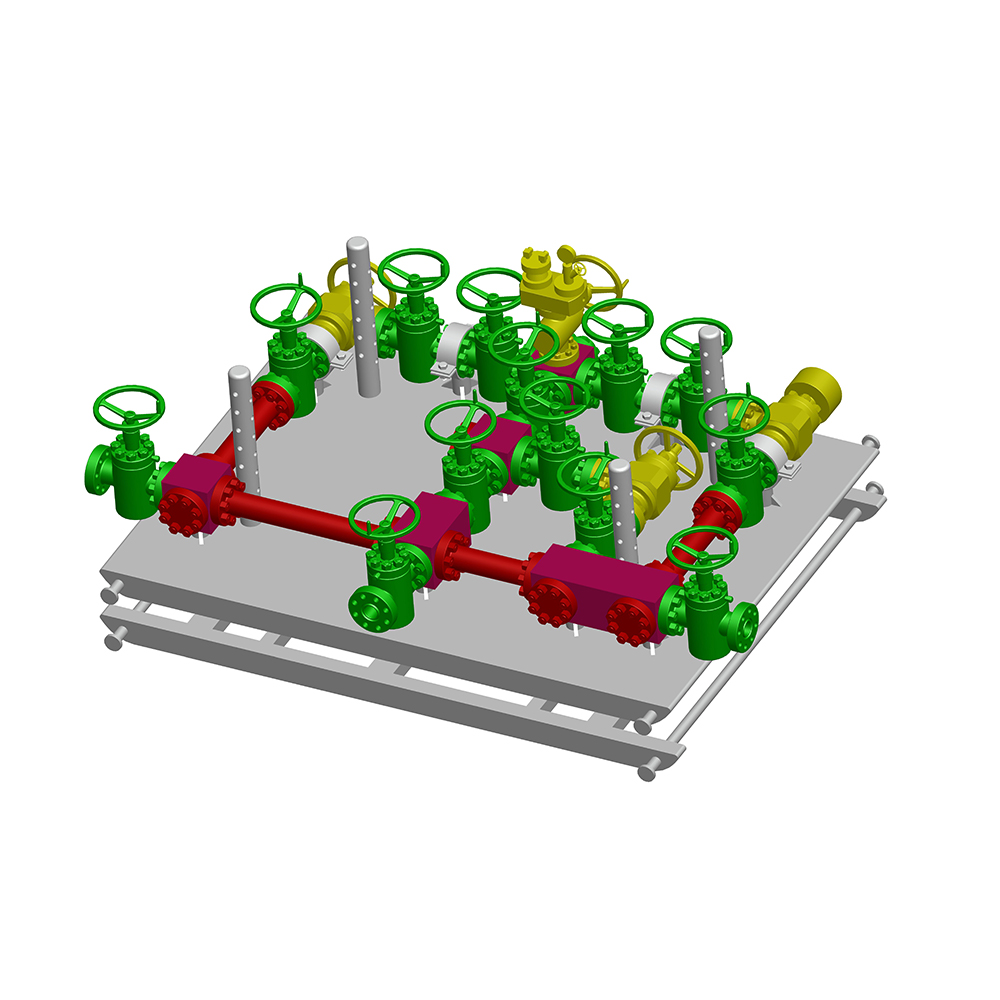

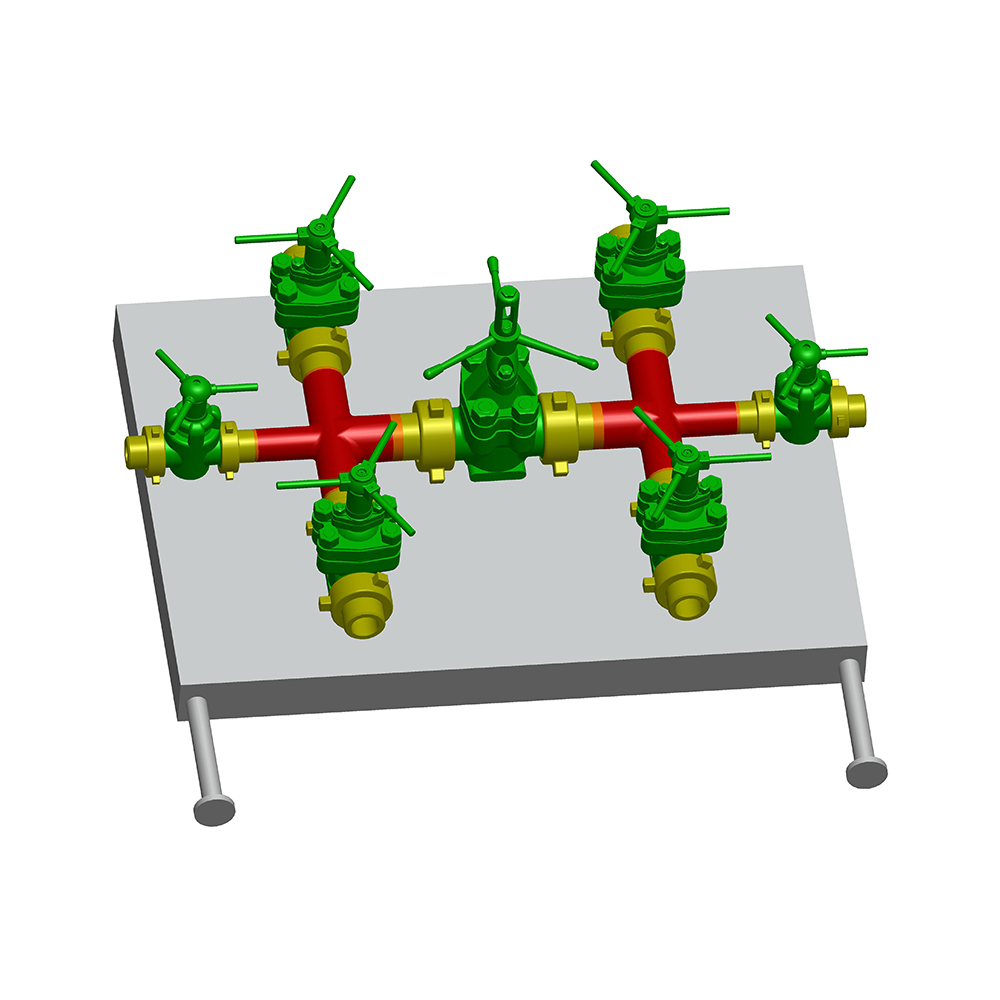

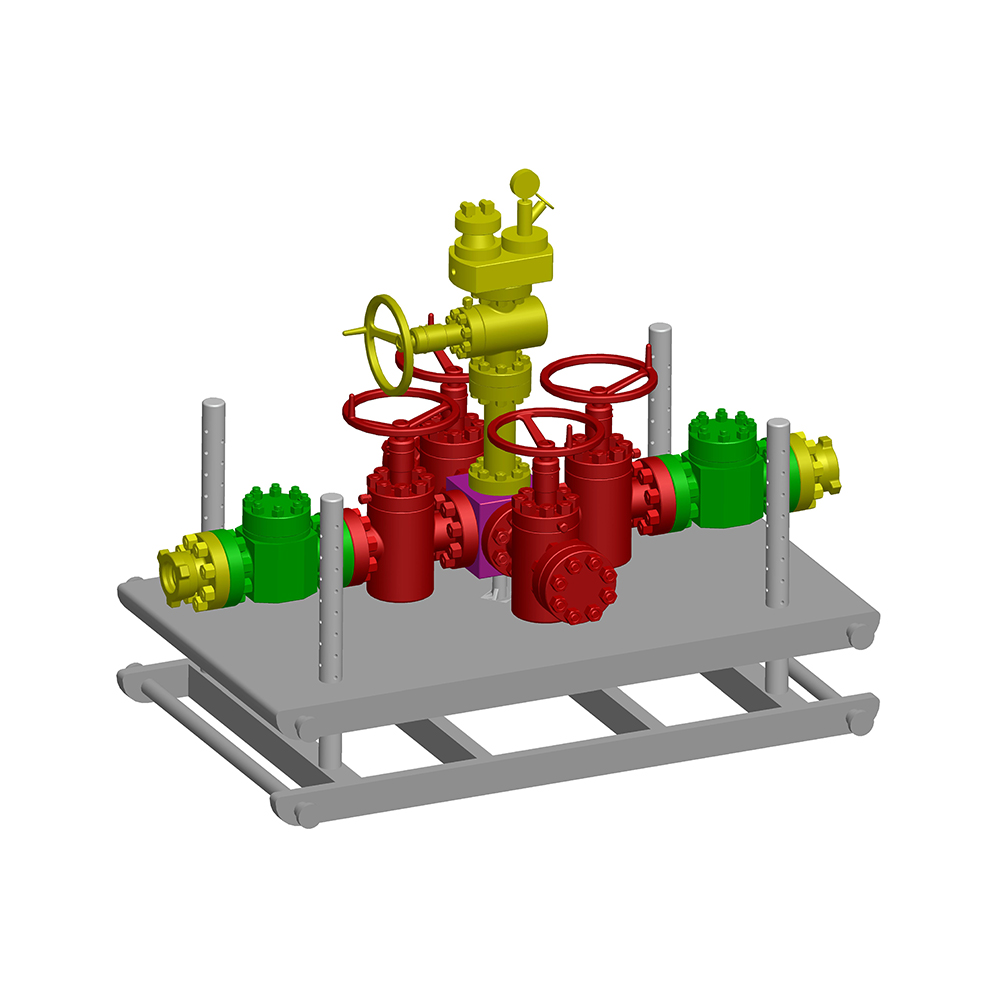

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

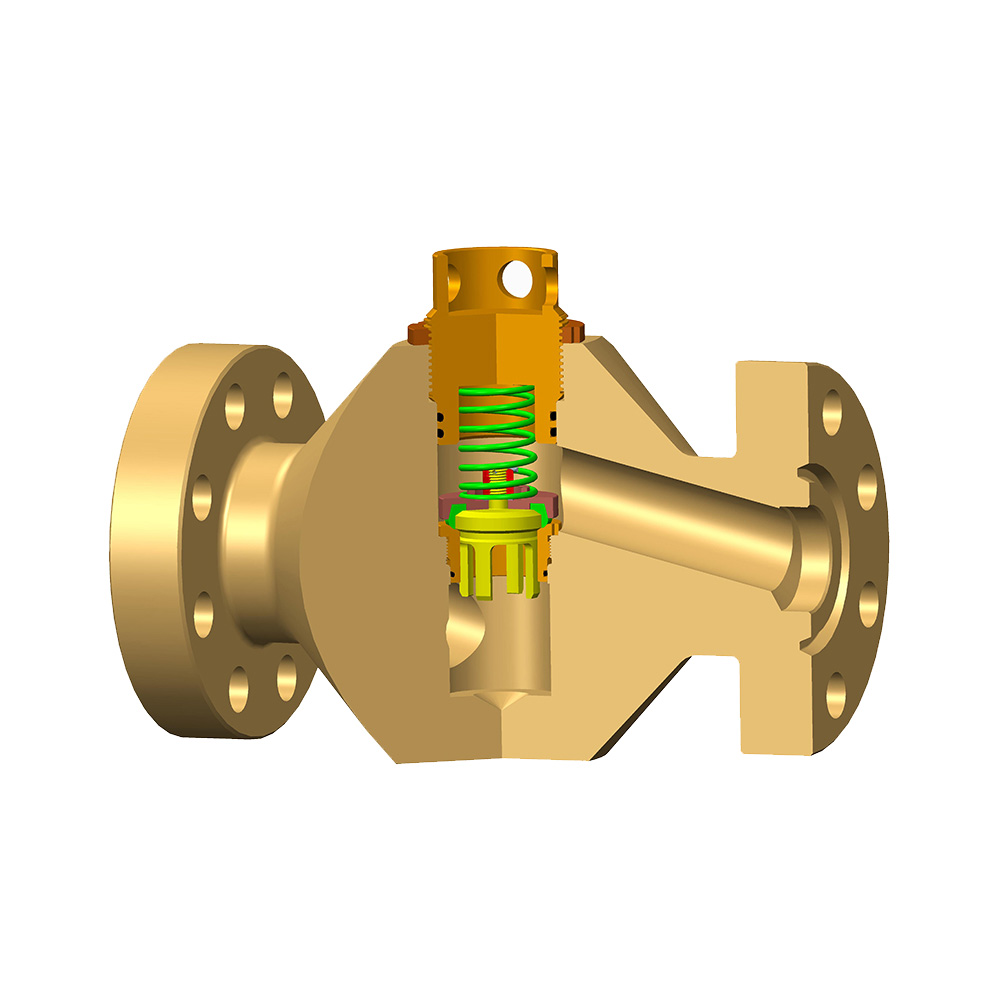

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

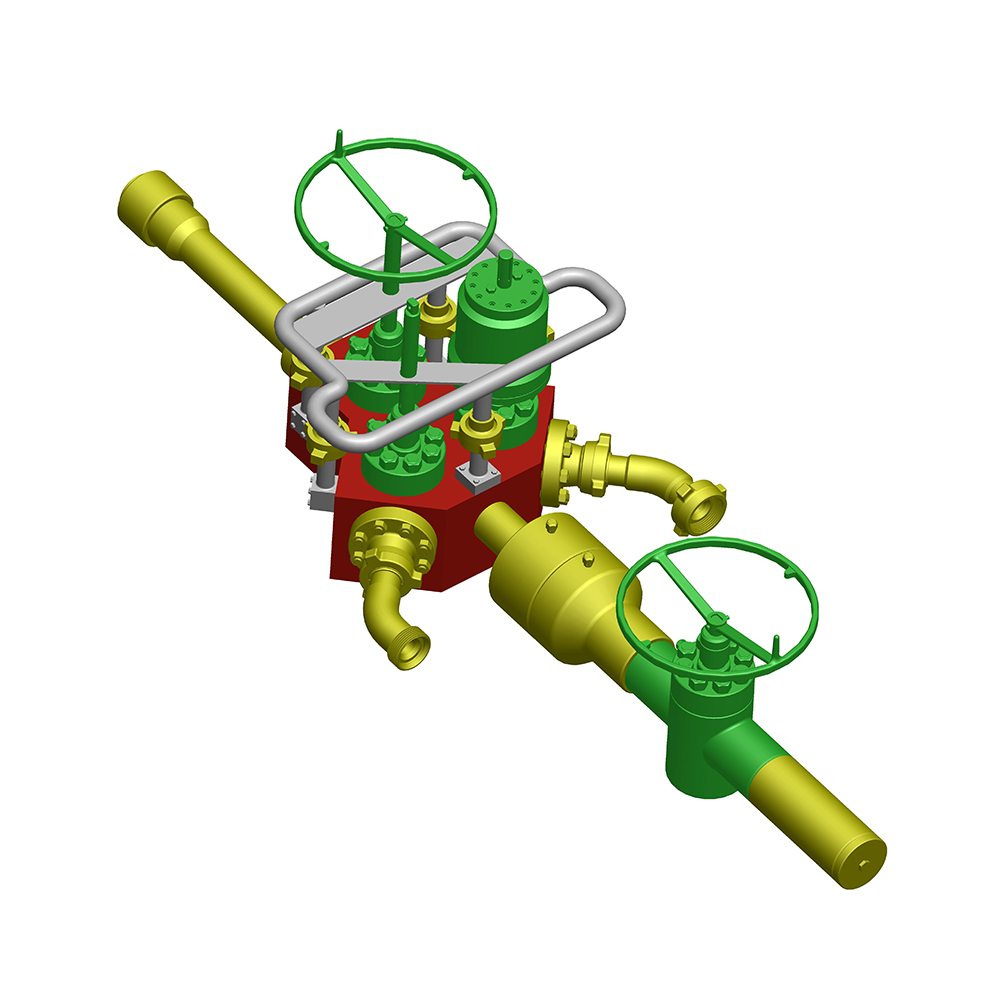

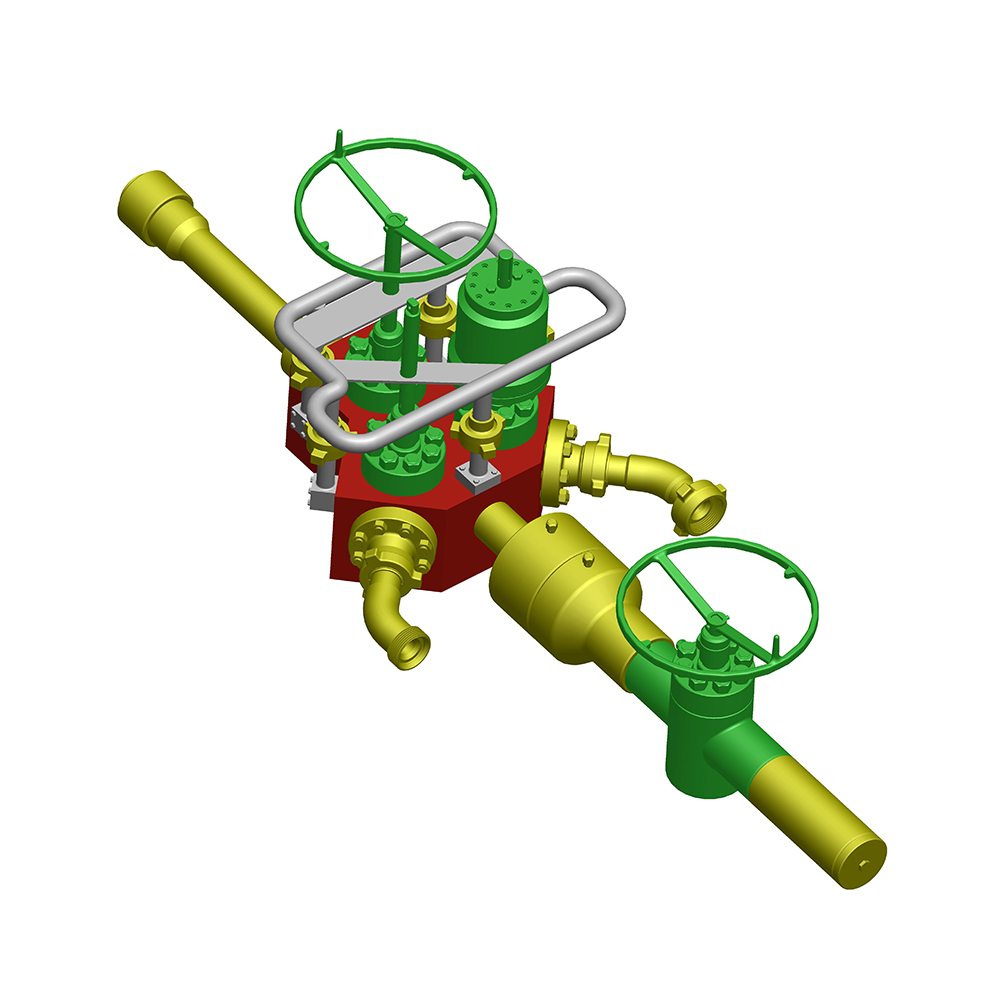

Flowhead sizes:1-13/16" ~9”Pressure Rating:5000psi- 15000psiMax.Tensile Rating:435,000 to 1,500,000 Ibs at 0PSIUpper and lower units are coupled with a load-bearing quick union for easy assembly and d...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

Flowhead sizes:1-13/16" ~9”Pressure Rating:5000psi- 15000psiMax.Tensile Rating:435,000 to 1,500,000 Ibs at 0PSIUpper and lower units are coupled with a load-bearing quick union for easy assembly and d...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details

Contact Zhonglin Support Team for any Inquiry

Mob:

+86-18066199628/ +86-18805110688

Email:

sales1@zhonglinoil.com / sales@zhonglinoil.com

Add: 88 Ronghua Road Yancheng New Hi-Tech Industrial Development Zone Yancheng, Jinagsu People's Republic of China