In drilling equipment, the performance of Drilling Equipment Valve is crucial. The material of the valve has a decisive influence on its performance.

Different materials have different characteristics, which directly affect the performance of the valve. For example, stainless steel has good corrosion resistance and can operate stably for a long time in harsh working environments. During the drilling process, various corrosive media such as salt water and chemicals are often exposed. Stainless steel valves can effectively resist these corrosions and ensure the sealing and reliability of the valve.

High-strength alloy steel has excellent strength and hardness and can withstand high-pressure and high-load working conditions. In drilling operations, valves need to withstand huge pressure and impact. High-strength alloy steel valves can ensure that they will not deform or be damaged under these extreme conditions, ensuring the safety of drilling operations.

In addition, some special materials such as titanium alloys and ceramics are also used in drilling equipment valves. Titanium alloys have the advantages of light weight, high strength, and corrosion resistance, and are suitable for some occasions with strict weight requirements. Ceramic materials have extremely high hardness and wear resistance, which can resist the scouring and wear of high-speed fluids and extend the service life of valves.

The selection of valve materials also needs to consider factors such as operating temperature, medium characteristics, and cost. In high temperature environments, it is necessary to select materials that can withstand high temperatures; for different media, such as oil, gas, water, etc., it is necessary to select materials that are suitable for them; at the same time, cost is also an important consideration, and it is necessary to select cost-effective materials while ensuring performance.

+86-18066199628

Product Search

Exit Menu

news

News categories

Product categories

RECENT POSTS

-

What are the specific application scenarios of valves in oil fields?

2024-06-01 -

Can the mud gate valve be closed quickly in the event of a blowout?

2024-06-02 -

What are the uses of valves for oil fields?

2024-06-10 -

Welcome to Zhonglin Oil Equipment!

2024-07-08 -

In which industries is GATE VALVE widely used?

2024-09-14

Drilling Equipment Valve: Material determines performance

-

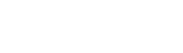

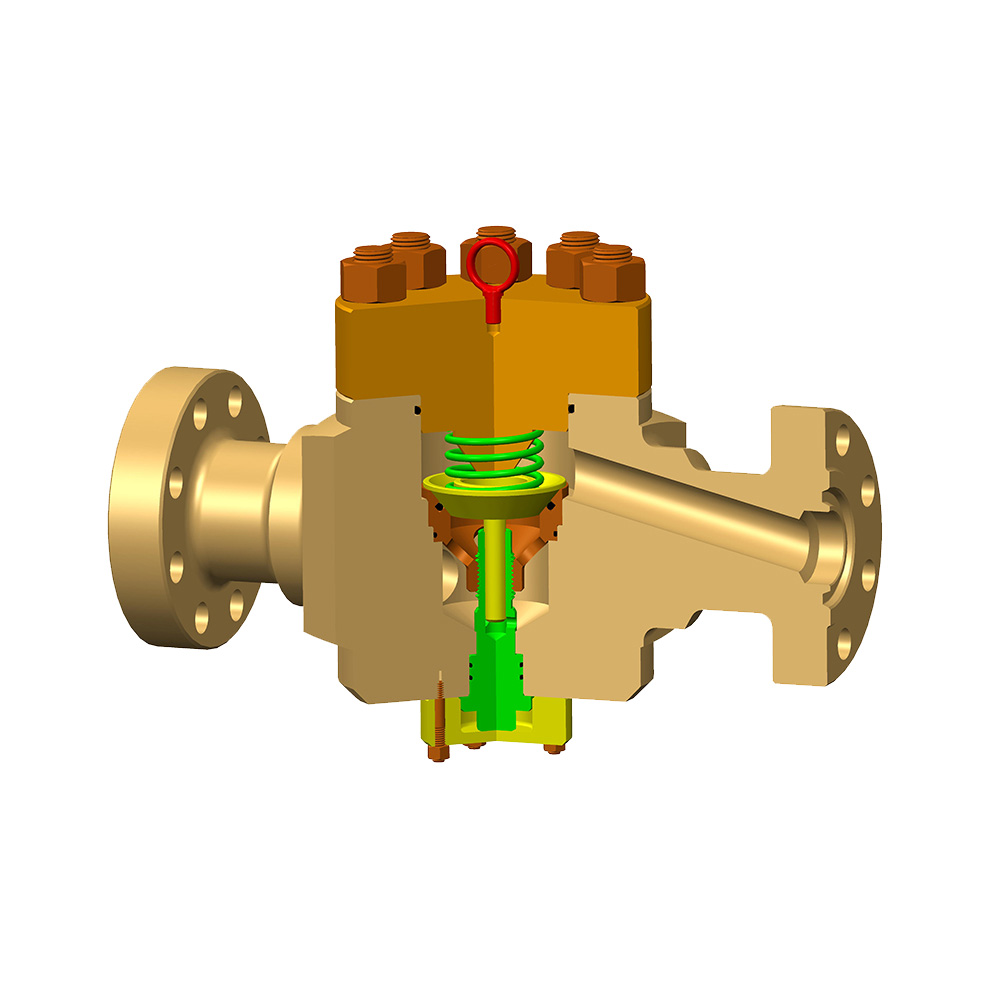

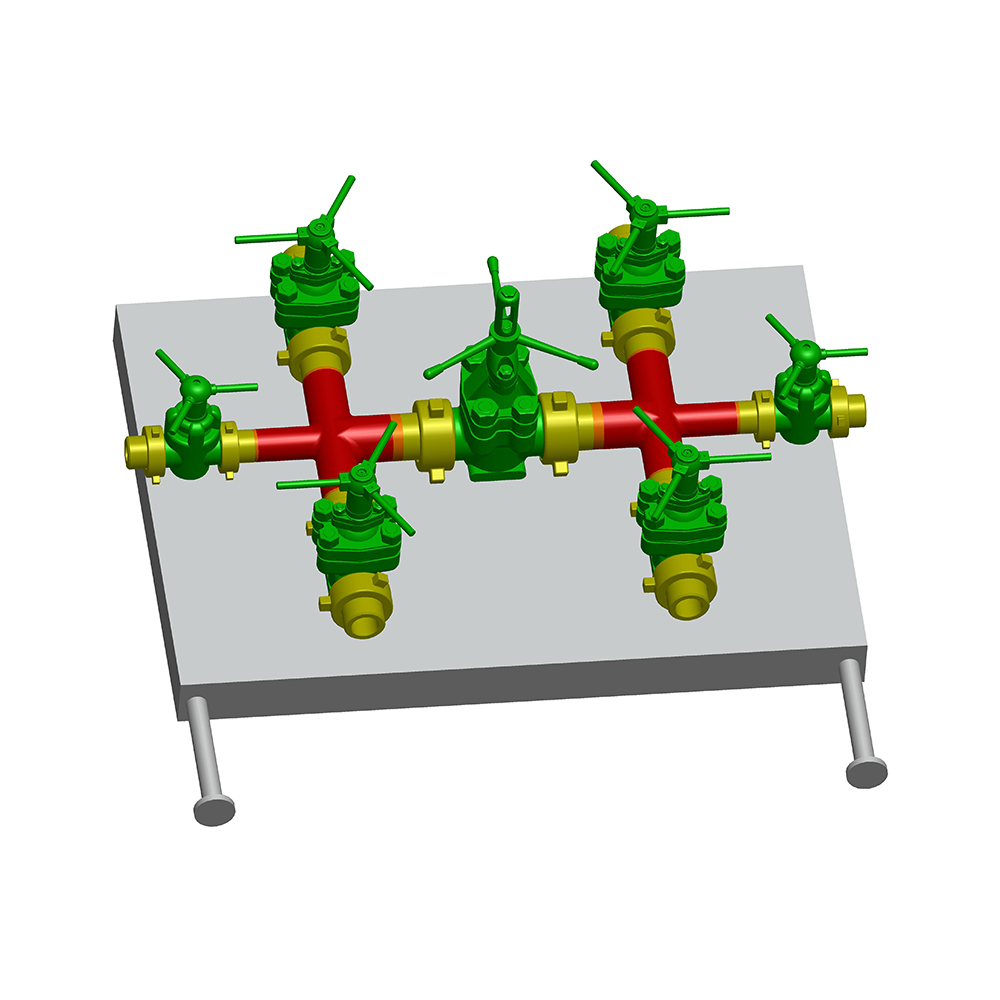

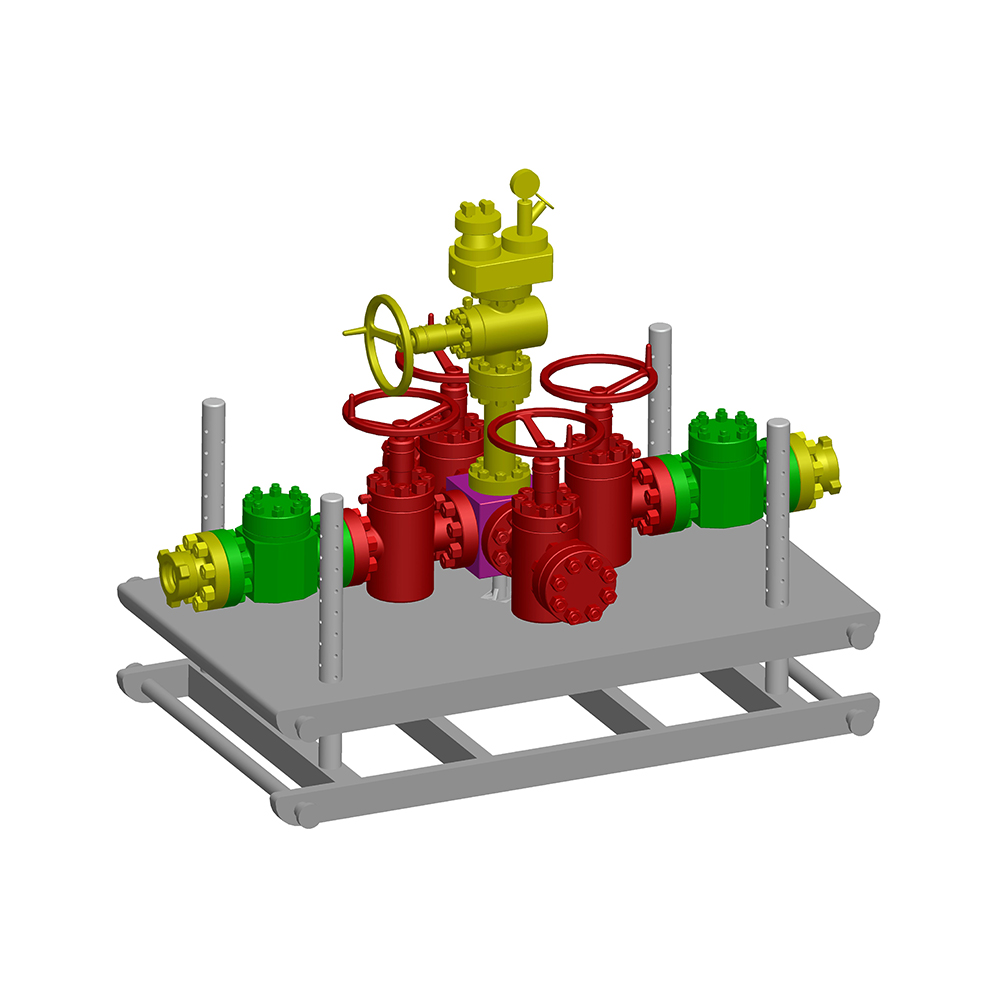

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

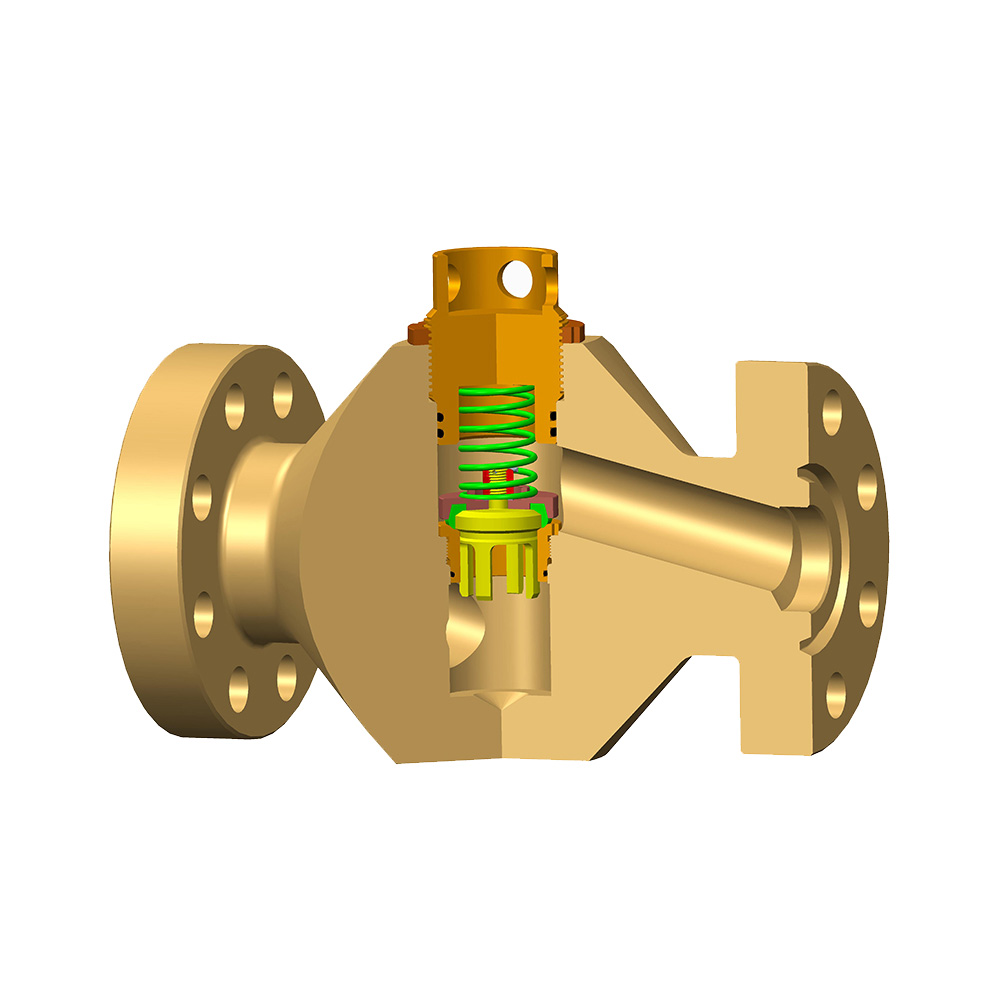

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details -

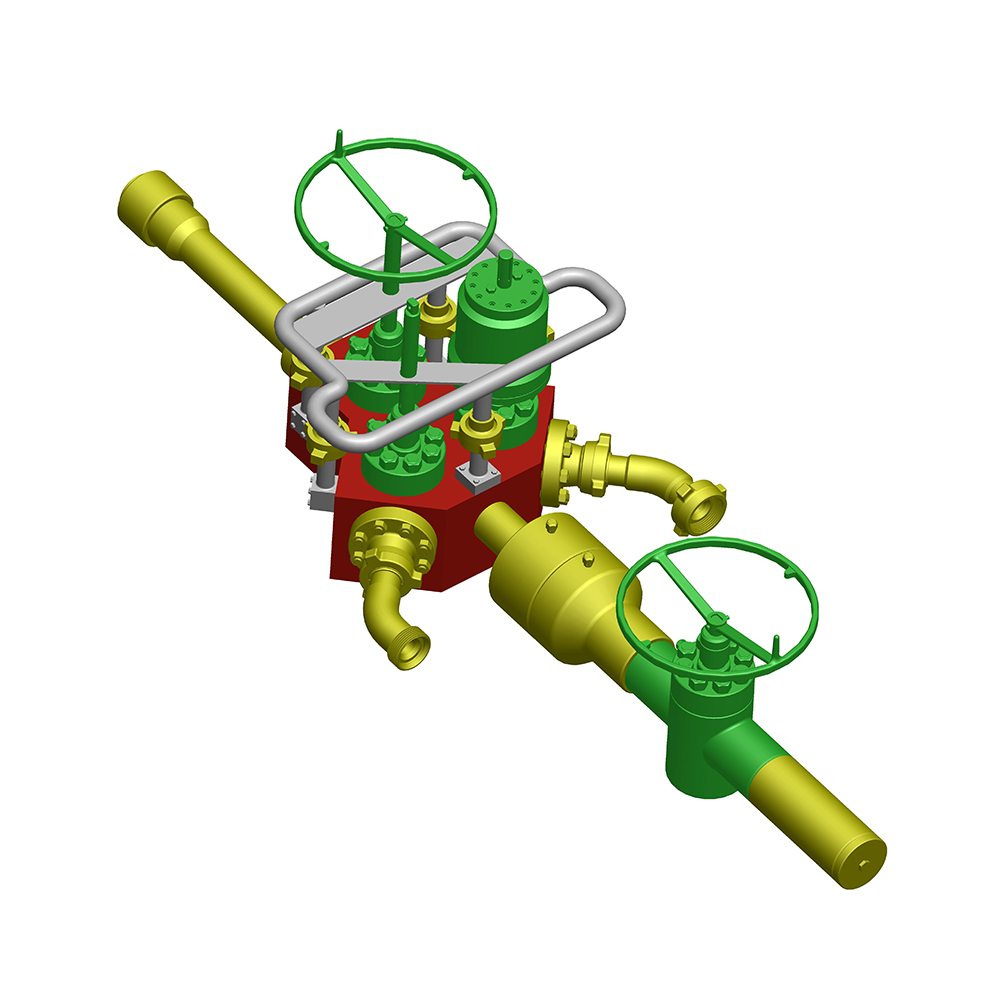

Flowhead sizes:1-13/16" ~9”Pressure Rating:5000psi- 15000psiMax.Tensile Rating:435,000 to 1,500,000 Ibs at 0PSIUpper and lower units are coupled with a load-bearing quick union for easy assembly and d...

See Details -

Choke and Kill manifold can effectively control the pressure inside the well and also can control the flow rate of oil gas and mud or other medium which returs from the well when it's used for drillin...

See Details

Contact Zhonglin Support Team for any Inquiry

Mob:

+86-18066199628/ +86-18805110688

Email:

[email protected] / [email protected]

Add: 88 Ronghua Road Yancheng New Hi-Tech Industrial Development Zone Yancheng, Jinagsu People's Republic of China